20+ Years of Experience

20+ Years of Experience

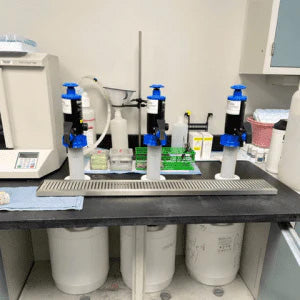

Core Competencies GoatThroat Pump's unique technology help companies reduce hazmat incidents and save money at their manufacturing facilities by preventing costly chemical spills and the associated cost of reporting and manufacturing downtime. The systems mitigate worker compensation claims by preventing workers exposure to hazardous chemicals and by eliminating repetitive motion and other injuries. • Used for specialty liquids including Skydrol LD4 for USAF • Prevents costly chemical spills and splashing • Controlled delivery of chemicals prevents waste and conserves inventory • Helps meet E.H.S. and sustainability requirements • R.C.R.A. empty barrels meet Government regulations • Prevents worker exposure to hazardous chemicals and emissions • Chemicals purchased in bulk (55 g) can save up to $2500 per month • 10 year life expectancy saves repeat purchasing of new equipment • Eliminates repetitive motion and other injuries • Mitigates worker compensation claims • Provides jobs for Americans with Disabilities Differentiators Companies use hazardous chemicals and flammable liquids in paint shops, tool and die rooms, HVAC and other locations throughout the manufacturing facilities. The liquids are dispensed from barrels and pails at the point of use. Dispensing these liquids with accuracy is critical. It is also important to so without a hazardous spill, without splashing liquids on to the user, and without exposing users to the vapor emissions. GoatThroat Systems are the only hand pumps which deliver these benefits. STATEMENT FROM RECENT CUSTOMER "Works great. Saves space being able to keep drums upright as opposed to tilting them to get product out. Back saver not having to tilt drums. Saves time: can pull from multiple drums using multiple GoatThroat's instead of needing to tilt one drum at a time. Cleaner, save product, less of a chance of anything spilling." Dennis, Ashcroft Manufacturing Company Data The GoatThroat Pumps Division of Westcott Distribution Inc. was founded in 2000 and operates from Milford, Ct. GT Pumps are manufactured in the USA and distributed worldwide. Westcott Distribution Inc. is a small, woman owned business. Nancy Westcott has been the CEO and Chief Equipment and Systems Designer since 2000. This is her third successful entrepreneurial business. DUNS Number: 021552471 CAGE Code: 3XWR9 SAM Registration: Active Accept Credit Card: Yes Business Size: Small WOSB Registered: Yes WBENC Certified: Yes NAICS Codes: 333914* 333913 333996 423830 *Primary PRODUCT AND SERVICE CODES 3590 J014 J037 J059 J099 3695 J015 J038 J061 J998 3990 J016 J039 J065 J999 4320 J017 J041 J066 4910 J018 J042 J067 4920 J019 J043 J068 4930 J020 J044 J071 4935 J025 J045 J072 4940 J029 J046 J073 4960 J030 J049 J079 5120 J031 J051 J080 6640 J032 J053 J087 6695 J035 J055 J091 6850 J036 J056 J093 Past Performance General Dynamics: Electric Boat, Quonset Point, Groton; 2015 - present Provided multiple pump systems for multiple locations for MEK, Acetone, Isopropyl Alcohol and other proprietary liquids to allow for EPA reporting of liquid consumption and vapor release. As well, the pumps eliminated exposure to hazardous chemicals and worker injuries from moving a 65 pound electric pump from drum to drum John Donlevy, Environmental Department, jdonlevy@gdeb.com, 401-932-9309 Lockheed Martin: White Sands, New Mexico; Liverpool, New York; Johnstown, Pennsylvania; Camden Arkansas; 2010 - present Provided multiple pumps systems for multiple locations for solvents including MEK, IPA and other liquids to control amount dispensed, reduce worker exposure to spills, splashes and emissions. NASA, Sandusky Ohio; 2016 to Present NASA need to transfer 30 barrels of Novec Fluids to a 1000 gallon container quickly. With the GT pneumatic system, they accomplished the entire job in 1 afternoon.