A safe harvest is a happy harvest. You know about this all too well if you work in the agricultural industry. The reality is that the delicious, succulent fruits and vegetables that we all eat actually go through quite a process during the time it takes to get from the farm to the table.

Farming requires the use of many different types of chemicals. Crops need to be protected or they simply won’t make it to grocery stores, farmers markets, and kitchen tables across the country. Safety is a top priority when using chemicals to protect crops during the growing season and harvesting process. That’s why it always feels like a breath of fresh air when a new innovation comes on the scene that can make the task of handling chemical materials safer and more convenient.

Today, we’re focusing on something that may be overlooked: a hand pump which will help you meet your HACCP requirements. Find out how an innovative hand-operated pump can make your growing season smoother by facilitating safety with plant protection products—there’s even something in it for your bottom line.

Are You Really Ready for the Upcoming Growing Season?

Does the stained, discolored, or continually wet floor tell a tale of recurring and frequent spills? That could be a big sign that you’re using a less-than-ideal method to decant or transfer liquids between containers. Many farms simply fall into a pattern of using the tip-and-pour method to move agrochemicals and liquids from larger containers to smaller ones. The problem with this method is that it is imprecise. Drums and pails can easily tip and fall, and the tip-and-pour method makes it difficult to pour the actual amount that you need. It creates a perfect-storm scenario where human error and the laws of physics conspire to make sure spills occur more often than is ideal or safe. Because the concentrates are so much more expensive these days, it is wise to be thoughtful about choices.

It is in the best interest of any farm or agricultural setting to have safer methods for decanting liquids in place. Spills are inconvenient at best; however, improper practices for transferring liquids could be viewed as negligence if an employee or visitor is injured as a result of liquid that has been left on the floor. Spills or splashing on an employee can lead to lost work days. And larger spills could pose environmental issues that could land you in hot water with environmental agencies.

Do you want to make the upcoming season a spill-free season? It’s time to reevaluate your method for transferring liquids and discover what many farms are doing to upgrade their dispensing systems simply and quickly. This could be the season that you create a safer environment by using a transfer pump for liquids that does the following:

- Eliminates spills and drips.

- Eliminates vapors.

- Allows you to store containers of liquid in the upright position.

- Prevents accidents.

- Prevents repetitive-motion injuries.

- Is considered to be PPE

You’re probably already in the thick of executing your growing season if you live in California, Florida, Arizona, Texas, or in the South. However, it’s not too late to begin implementing some changes that will help you sail through the rest of the season more easily or prepare for the season after this one. You’re very likely in the process of diligently planning for the upcoming growing season if you’re located in the Midwest or the Northeast. Don’t let these precious few weeks between now and when you’ll need to begin working on your crops pass without working on a better plan for holding and dispensing chemicals. You could be all set and ready to go with an elevated process for handling chemicals before it’s time to put the first seed in the ground.

Why a Good Pump Plays a Big Role in Creating Good Agricultural Practices

You handle many different liquids on a daily basis if you work in or manage an agricultural environment. Most of the chemicals you deal with are used to protect and nourish the crops you’re cultivating. This includes things like fertilizers, fungicides, hormones, and wetting agents. You may also need to dispense crop protection products that are used for plants in greenhouses, crop fields, and fruit groves. Each crop-related chemical comes with its own set of instructions on the label for proper handling including post-harvest sanitation liquids.

Between 1,800 and 3,000 occupational incidents related to exposure to agrochemicals are reported every year, and what’s more, an environment where spills are present could mean that your farm or facility is not compliant with EPA’s WPS rules (Worker Protection Standards) and OSHA regulations.

Farms need to have strict and heavily enforced rules regarding who has access to agricultural chemicals and how they must handle those chemicals. Specific training regarding not just how to handle and transfer chemicals, but also how to report spills, should always be strictly observed to eliminate compliance issues.

How Can You Handle Liquids and Chemicals with Extra Safety in a Farm Setting?

You probably deal with the need to decant concentrates into smaller containers in order to mix or dilute them on a regular basis during harvesting season at your farm. Or you need to deliver the materials directly to the mix tank. That means you already know about all of the challenges that can go along with what seems like a simple and routine task. Incidents resulting from liquid spills can lead to serious injuries, personal lawsuits, and fines from the Environmental Protection Agency (EPA). You can take the guesswork out of transferring liquids by upgrading to a GoatThroat pump at your farm.

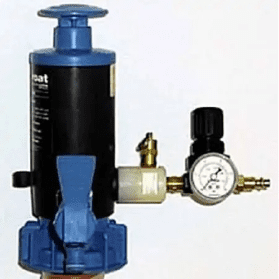

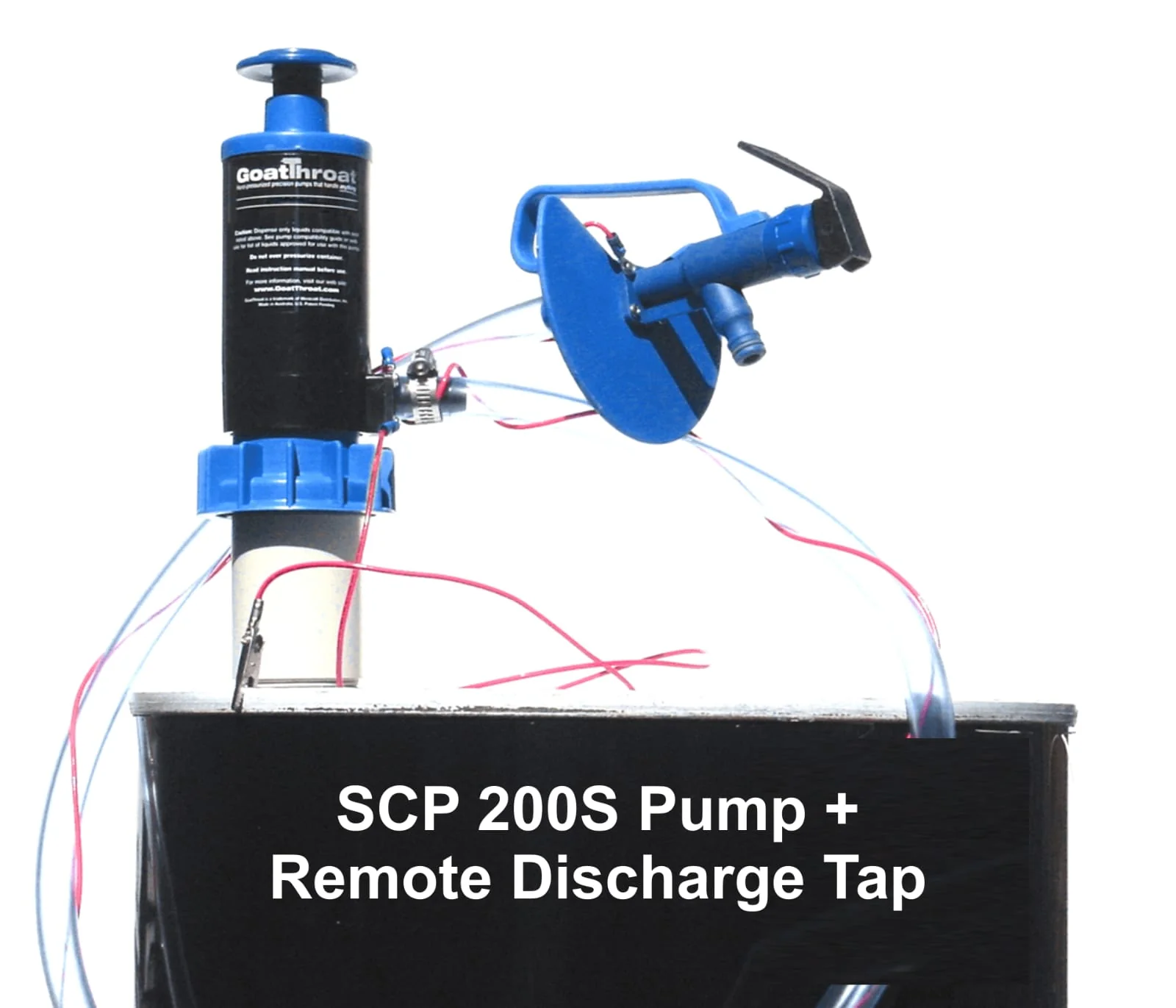

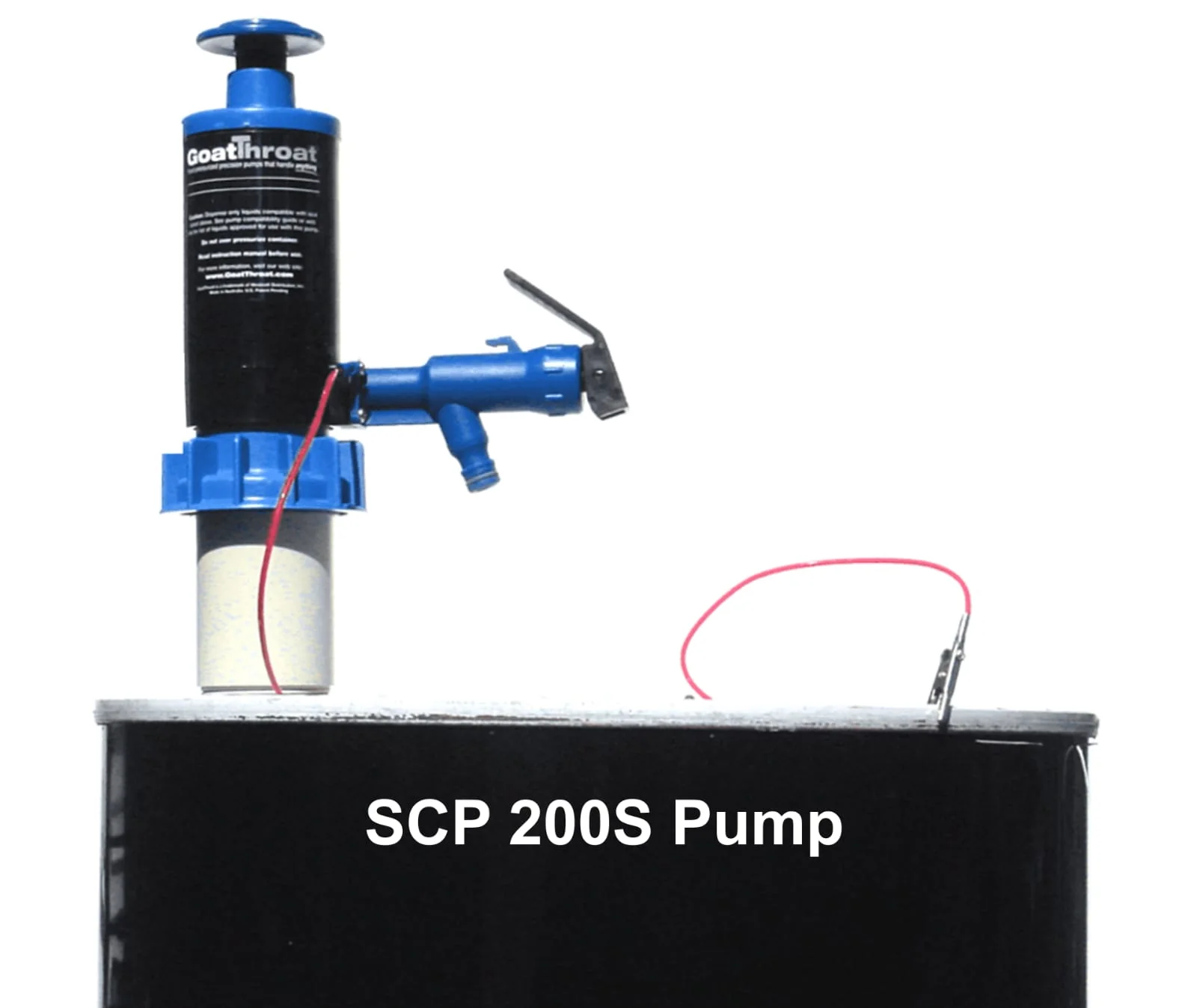

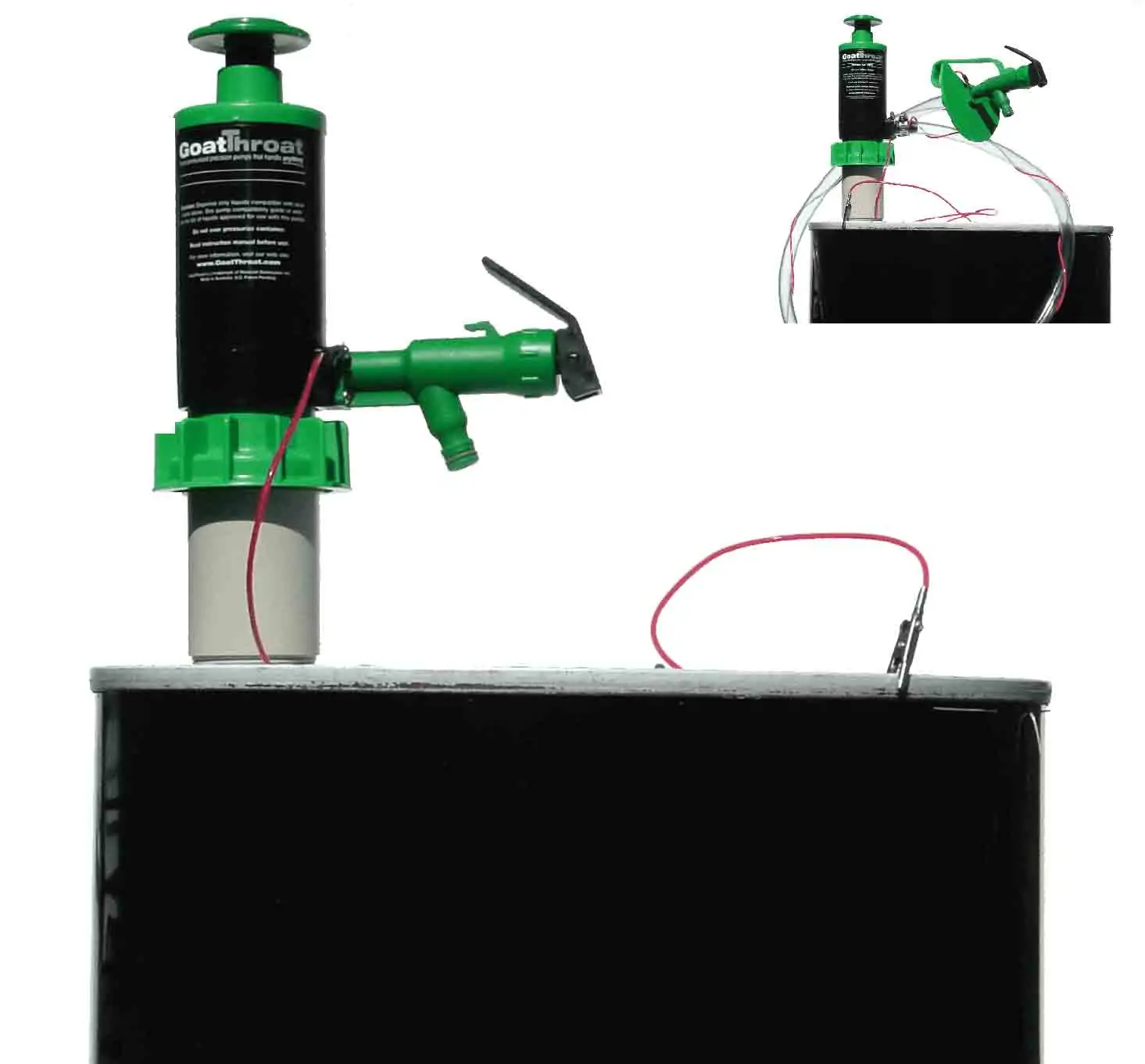

A few strokes of the plunger can accurately deliver liquids from any size container to your measuring device without any of the risks that go along with the hand pumps that are popular on the market today. A GoatThroat pump can be safely used with more than 1,700 liquids, including fuels, fertilizers, hormones, and pesticide concentrates, and works with containers that are just a few gallons and drums of up to 55 gallons.

A GoatThroat pump is designed with a one-touch, spring actuated mechanism that allows pesticide handlers to execute a controlled, steady transfer of liquids from one container to another, and the flow rate can be adjusted from gallons to drops based on your needs.

Growers tend to dedicate 1 pump to each category of liquids: 1 pump for herbicides, 1 pump to insecticides, 1 pump to wetting agents, 1 pump to fungicides and 1 pump to fertilizers. A thorough cleaning with water between chemicals is very important.

The Value of Closed Systems

Keeping workers safe is not just a best management practice, it is the law. The federal Worker Protection Standard was revised in 2015 and now provides a greater focus on reducing pesticide exposures. A closed system of transferring chemicals reduces unnecessary exposures by providing controlled delivery of chemical products without fear of worker exposure, over-pouring, spilling, or releasing vapors.

A closed system moves the material from point A to Point B without leaking or causing exposure to the handler. Dry-lock fittings on the connection points of all hoses and other connection points mean no applicator exposure and helps guarantee safety. Liquids are transferred from the source container, into the measuring system, and then to the mix tank. For larger amounts of liquid plant protection products, some systems draw the liquid through a meter directly into the mix tank. Custom blended and dilute products can also be delivered to mix tanks or backpack sprayers efficiently. Once empty, the only thing necessary is to triple rinse the container, leaving it ready for recycling.

The Cost-Savings Angle

Creating a safer environment is reason enough to upgrade your process for transferring liquids. The bulk aspect of ordering and storing agricultural materials means that most people who run or manage farms purchase chemicals and other liquids in large batches as part of cost-saving measures. While smart, this does create the need to transfer liquids from bulk-sized containers into containers that are more manageable. This can be difficult if you don’t have a system that offers a predictable, controllable way to pour liquids.

Every drop of liquid stored in containers and barrels represents money that has been invested in your farm. Why would you want to watch those drops slip away little by little? Each small spill adds up over time to represent a significant amount of money. Having a more efficient method for transferring liquids and eradicating spills can leave more money for your bottom line.

The no-spill technology of GoatThroat Pumps helps to cut down on inventory waste. Many clients who upgrade to a GoatThroat pump actually report that they pay for themselves within less than a season due to the fact that a GoatThroat pump outlasts traditional pumps by four to five times!

Why You Can Bet the Farm on a GoatThroat Pump

Do you have a streamlined, safety-oriented plan for transferring liquids between containers? Discover the versatile manual pump that many insurance companies consider a best-practices resource. GoatThroat pumps offer an efficient way to cut down on hazards and cut back on costs. Find out more via our Agriculture Industry page about how GoatThroat pumps can help you have a better growing season.