Are spills a daily worry at your laboratory? The transference of chemicals is one of the most common activities in a pharmaceutical laboratory. However, the reality is that most supervisors and operations managers are allowing some pretty big oversights to occur in their labs when it comes to how materials are transferred. It makes sense to purchase barrels and pails of chemicals from a business perspective at first glance. However, there is more than meets the eye when it comes to transferring usable amounts of chemicals into smaller containers. There are risks that need to be addressed and avoided. Keep reading to learn about a pump that can do the following:

- Reduce or eliminate the risks of spills and injuries as a result of chemical transfers.

- Prevent leaking and control emissions.

- Eliminate the fear of ignition incidents with flammable liquids.

- Eliminate the need to waste money by ordering smaller chemical quantities at higher rates.

- Create a fluid flow that reaches a rate of up to four gallons per minute.

- Last four to five times longer than traditional pumps.

Many facility managers, operations supervisors, and general lab workers are familiar with something that’s known as the tip-and-pour method. A red flag should be going up if this method is currently being used at your laboratory. The reality is that this method puts workers at risk for exposure to some potentially dangerous materials. Major risks are present whenever workers are transferring chemicals from one container to another due to splashing, over-filling, and the likelihood that the person doing the transfer could lose control over the larger container.

There are countless examples of these risks having been realities in lab environments in the past. The results are often difficult and costly to fix. In addition to the physical harm that workers can endure, highly valuable projects can be compromised and work can be lost. Don’t let your laboratory become the subject of an accident or incident that could have been prevented. See more at https://injuryfacts.nsc.org/work/work-overview/work-safety-introduction/.

The Importance of Using a Sealed Pump System to Prevent Spills

It’s not uncommon to see liquids transferred by applying a spigot and tipping a container on its side if you hang around a lab long enough. This is the tip-and-pour method in motion. This method does seem to make it easy to access liquids. However, it is extremely tedious and risky when compared to alternative methods that could be used. The process of inserting a spigot is often a challenge for laboratory workers. There is a risk of leakage every time this action is performed due to the fact that the container is often left to rest on its side. The risk of a spill is quite real. What’s more, it is entirely possible that the spigot could be knocked out of place. That means a massive spill.

Spigots can be quite problematic in general. Of course, this is difficult to know unless you spend quite a bit of time working with liquid transfers. Spigots appear to be easy to work with at first glance due to the fact that gravity works with the liquid to create a smooth flow when a barrel is at capacity. It’s a different story once liquid levels begin to drop. There is a slowdown point once the barrel is no longer at full capacity. This is often when trouble begins for laboratory workers. It’s often necessary to move the container around and manually increase the angle of the tipping motion in order to get the flow going again. Some laboratory workers actually opt to simply leave the remaining liquid in the container and start the process again with a full container. This can result in the loss of untold amounts of money over time.

It’s clear to see that the tip-and-pour method is nothing more than a risky and potentially costly hassle. What is the better solution? Laboratories are turning to GoatThroat® Pumps to ensure easy, safe pours every time.

What are GoatThroat Pumps? A GoatThroat Pump is a self-sealed system that is made to be placed on top of any container. There is never any need to lift or tip a container when operating a GoatThroat Pump. The pump is manually pressured by hand pumping. That means that the person extracting the liquid remains in total control. In addition, this allows you to always experience the same level of flow as the liquid level inside the container goes down.

The pump allows for adjustments to ensure that the flow is always exactly what you want. A control valve on the output pump can be adjusted to prevent the issue of overfilling a container and wasting content. The most important thing about a GoatThroat Pump is that it is capable of eliminating the most common causes of laboratory spills. Being proactive about spills is much better than investing time, money, and resources into remediation and cleanup once a spill has already occurred.

The OSHA Factor

You’re probably already aware of the fact that the Occupational Safety Health Administration (OSHA) sets specific guidelines for pharmaceutical companies and similar laboratories regarding the use of chemicals. These highly important guidelines are meant to protect all employees from overexposure to toxic, flammable, or otherwise harmful chemicals. Strict OSHA rules are in place across the country regarding the amounts of vapors and emissions from chemicals that employees can encounter and be exposed to while in the workplace. This includes defined rules for how chemicals should be stored and dispensed. GoatThroat Pumps help laboratories meet or exceed all of these requirements.

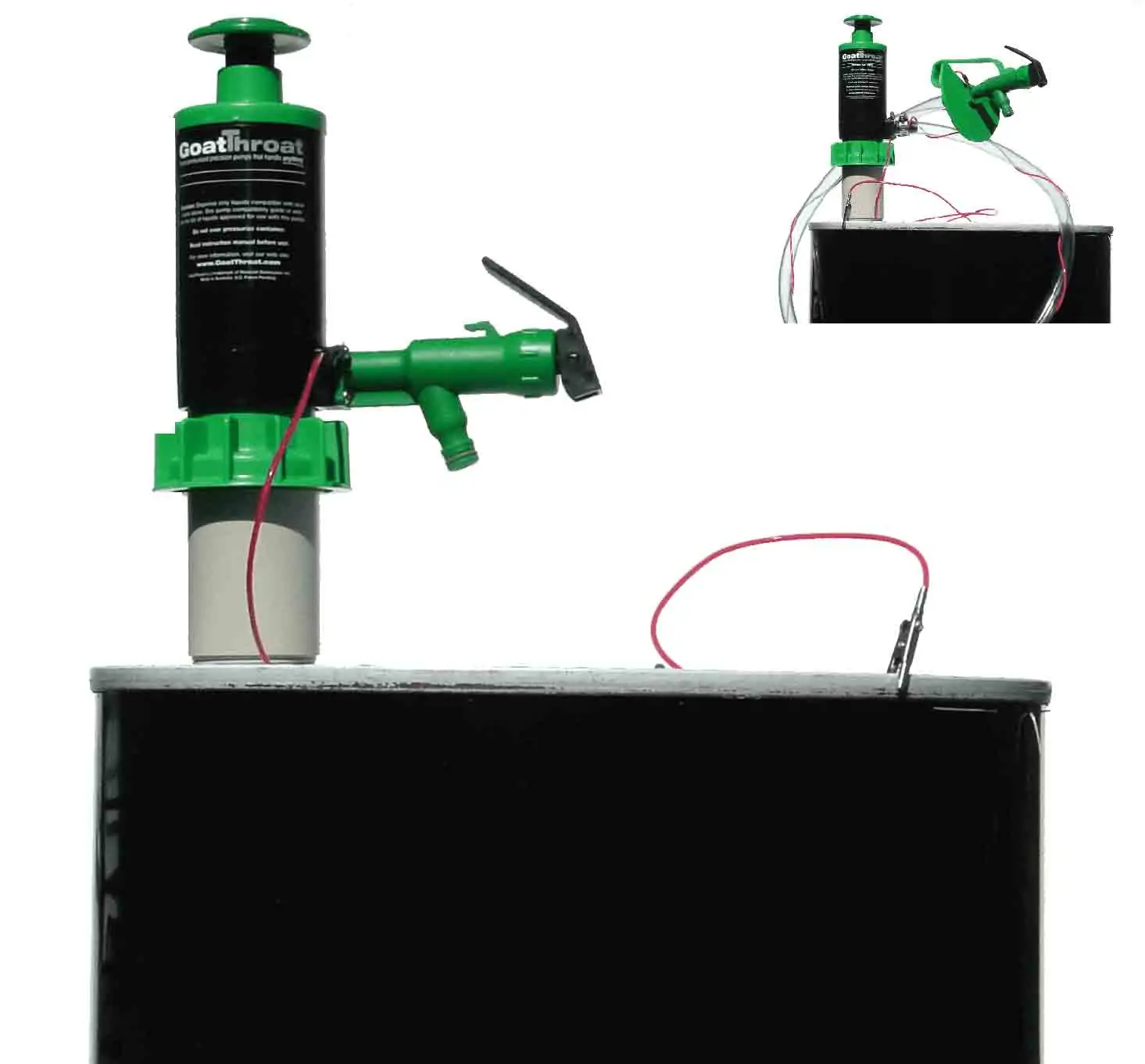

The GoatThroat SCP groundable line meets the National Fire Protection Association (NFPA) 30.18.4.4.1 and NFPA77 standards. The GT line of pumps is constructed from food-grade materials. This is done to prevent any potential contamination when the systems come in contact with food materials or liquids which are used in food processing facilities. All of the pumps are sealed-system pumps. In addition to preventing contamination of liquids, this feature also helps to eliminate vapors and prevent other emissions from escaping from containers. GoatThroat Pumps are rated to come into contact with more 1,700 different chemicals.

Here’s How GoatThroat Pumps Reduce Risks Around Volatile Liquids

Volatile chemicals are used within the pharmaceutical and beauty industries on a regular basis. These include common materials like acetone and various alcohols. Laboratories are tasked with the responsibility of handling these flammable materials in very specific ways. Most laboratories have special storage areas and dispensing zones for these categories of liquids. What’s more, most companies are actually willing to purchase smaller quantities at higher prices simply to reduce the risks associated with such flammable chemicals. That means throwing money away aside from the recycling of all of those small bottles. Safely transferring these materials from larger containers to smaller ones is no simple task. An ignition event could be triggered by attempting to use non-grounded pumping systems during the transfer process. This isn’t the case with GoatThroat Pumps.

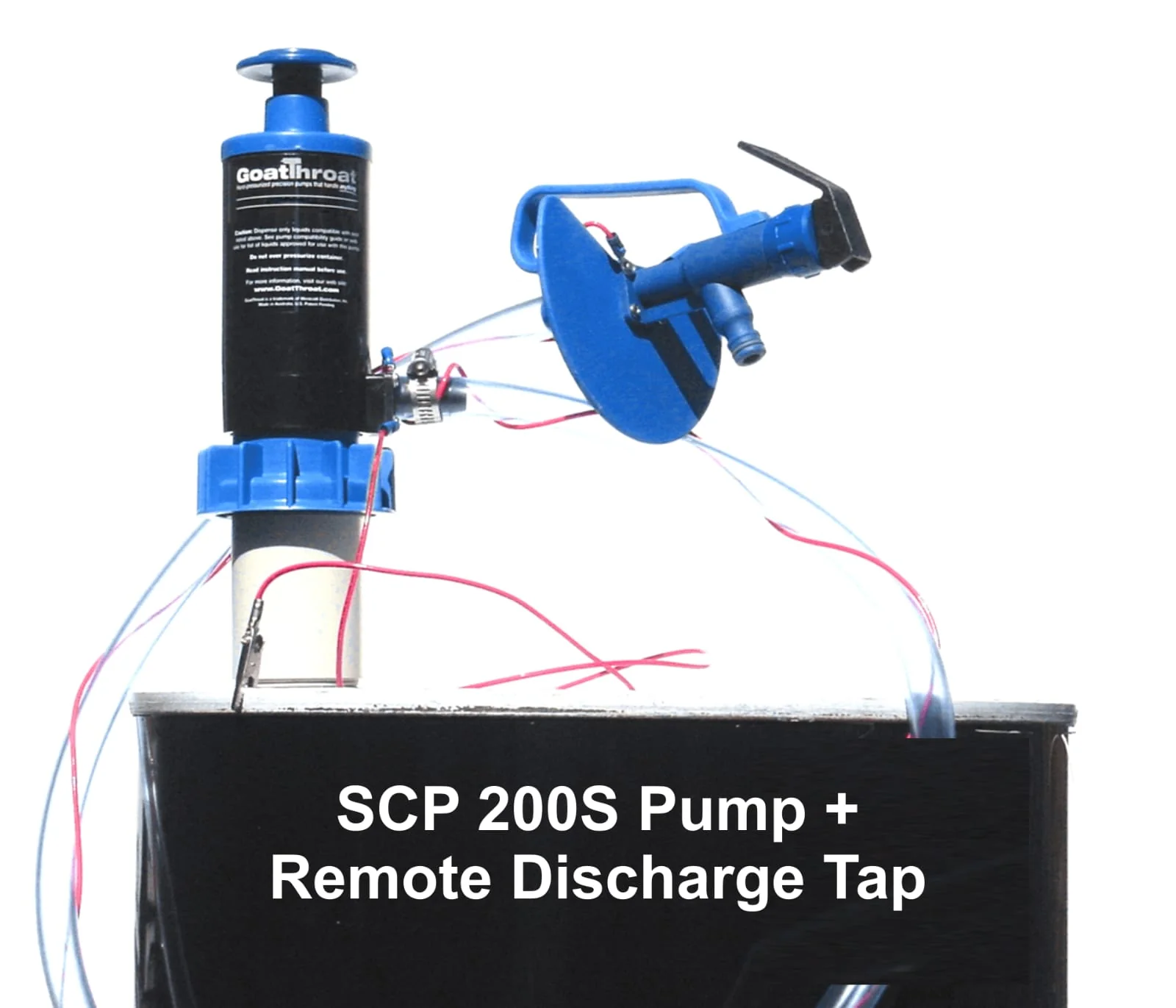

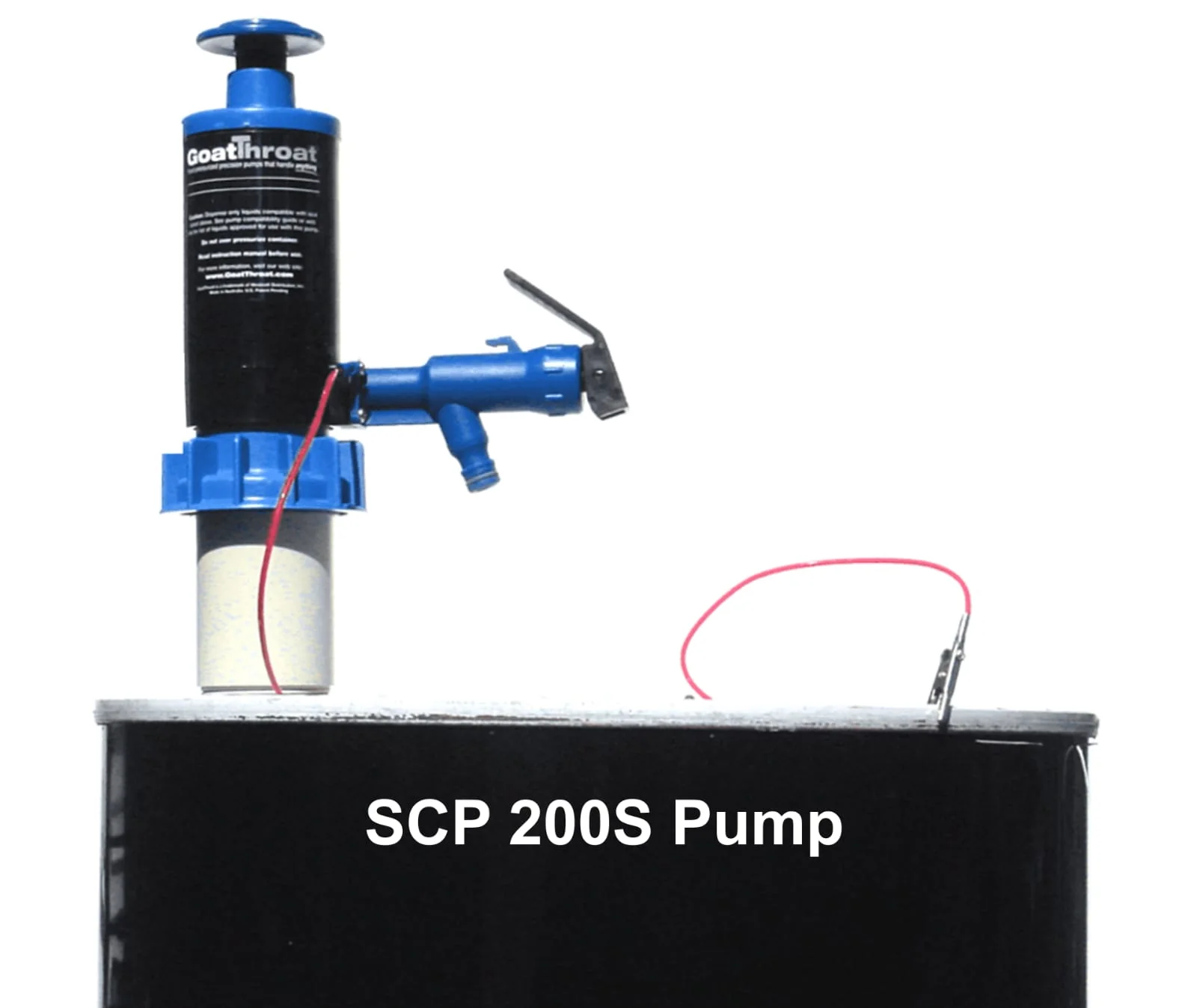

What does it look like when a GoatThroat Pump is in action? A GoatThroat Pump is manually pumped to build small amounts of pressure – < 6psig, the spring actuated control valve is opened by hand and the liquid comes out as fast or as slow as you want. Risk is essentially entirely eliminated through the combination of grounding and bonding wires that are in place. In addition, groundable plastic is used – which is as effective as metal in conducting static away from the system. GoatThroat allows you to create a safer working environment for employees. It is also possible to enjoy cost savings by purchasing lab liquids in bulk at reduced rates.

It becomes pretty clear why GoatThroat Pump is the safer alternative to other methods once you learn about its cutting-edge engineering and safety-minded features. Another impressive quality is its durability. The GoatThroat manual pump provides labs with a tap system that is simply more durable than other hand pumps that are available. Most hand and electric pumps suffer from a problem related to worn-out parts. Parts on these designs are notorious for wearing out prematurely, frequently with dramatic effect. Customers from around the country have reported that manual GoatThroat pumps last four to five times longer than other pumps available on the market.

The look and operation of the GoatThroat Pump might seem just a little bit familiar to you. That’s because the GoatThroat Pump actually operates in a way that’s very similar to how a beer tap operates. Most people haven’t spent a ton of time contemplating how a beer tap works. However, most of us are familiar with the fact that beer taps are designed specifically to ensure a perfectly portioned, clean pour every time. These taps allow the person pouring the beer to control how it is dispensed in a smooth, intuitive way. The same essential design is what is behind the consistent, predictable flow delivered by GoatThroat Pump.

Saying that GoatThroat Pump works exactly like the tap down at the local pub is a bit of an oversimplification. However, the mechanics behind both are very similar. The GoatThroat Pump takes the simple application of a beer tap to the next level. The last thing you want in a laboratory setting is a surprise. That’s why our revolutionary pump is designed to make it easy to plan and execute an outcome. What’s more, the GoatThroat Pump is easy to operate and maintain. We’ve reduced the number of moving parts to only 3 as a way to take the work out of transferring liquids. This simple, bare-bones design cuts down on maintenance and eliminates the need to worry about all of the output and safety issues related to using a pump that relies on electricity to operate.

The Pump That Works for Your Laboratory

The GoatThroat Pump has quickly become a favorite among laboratories and manufacturing companies in all industries. The efficiency of the system ensures that emissions, spills, and waste are all things of the past. The GoatThroat line of pumps consists of several different models that are designed to work with more than 1,700 different chemicals. These pumps can fit anything from a two-gallon bottle to a 55-gallon drum when the proper adapters are used. Our standard pumps are designed for food-grade products and non-flammable products. We also offer pumps that are designed to handle volatile chemicals. In addition to our eight distinct lines of pumps and hose systems, we also develop and offer several specialty products for our clients.

Is it time to upgrade the way your laboratory transfers liquids? Put GoatThroat Pumps to test at creating safe, seamless transfers. Our pumps are all manual and self-sealed systems that safeguard laboratory environments and employees from leaks and keep emissions under control. It’s okay if you’re not sure which type of GoatThroat Pump is the best fit for your pharmaceutical company or laboratory. Our friendly customer service staff is here to answer all of your questions and help you discover the right solution. We can offer a pump to you based on your location and intended application. The GoatThroat Pump team is here to help you create a safer laboratory environment for workers, save money, and meet all OSHA and chemical-use regulations.