Maintaining Food Safety

Food safety is a critical concern for any business involved in the production, processing, or handling of consumable goods. A sanitary food-grade barrel pump acts as a reliable tool for transferring liquids such as oils, syrups, sauces, and other ingredients, ensuring that they remain uncontaminated throughout the process. The use of FDA-compliant plastic guarantees that the pump meets the highest standards set by the U.S. Food and Drug Administration (FDA), certifying its suitability for use with food products.

Hygienic Design and Construction

A top-quality sanitary barrel pump is engineered with hygienic design principles in mind. It features smooth surfaces and crevice-free construction, minimizing the risk of bacterial growth and facilitating thorough cleaning and sanitization. The FDA-compliant plastic used in its construction is resistant to chemicals and corrosion, ensuring the pump remains durable and safe for prolonged use in food processing environments.

Versatile and Easy to Use!

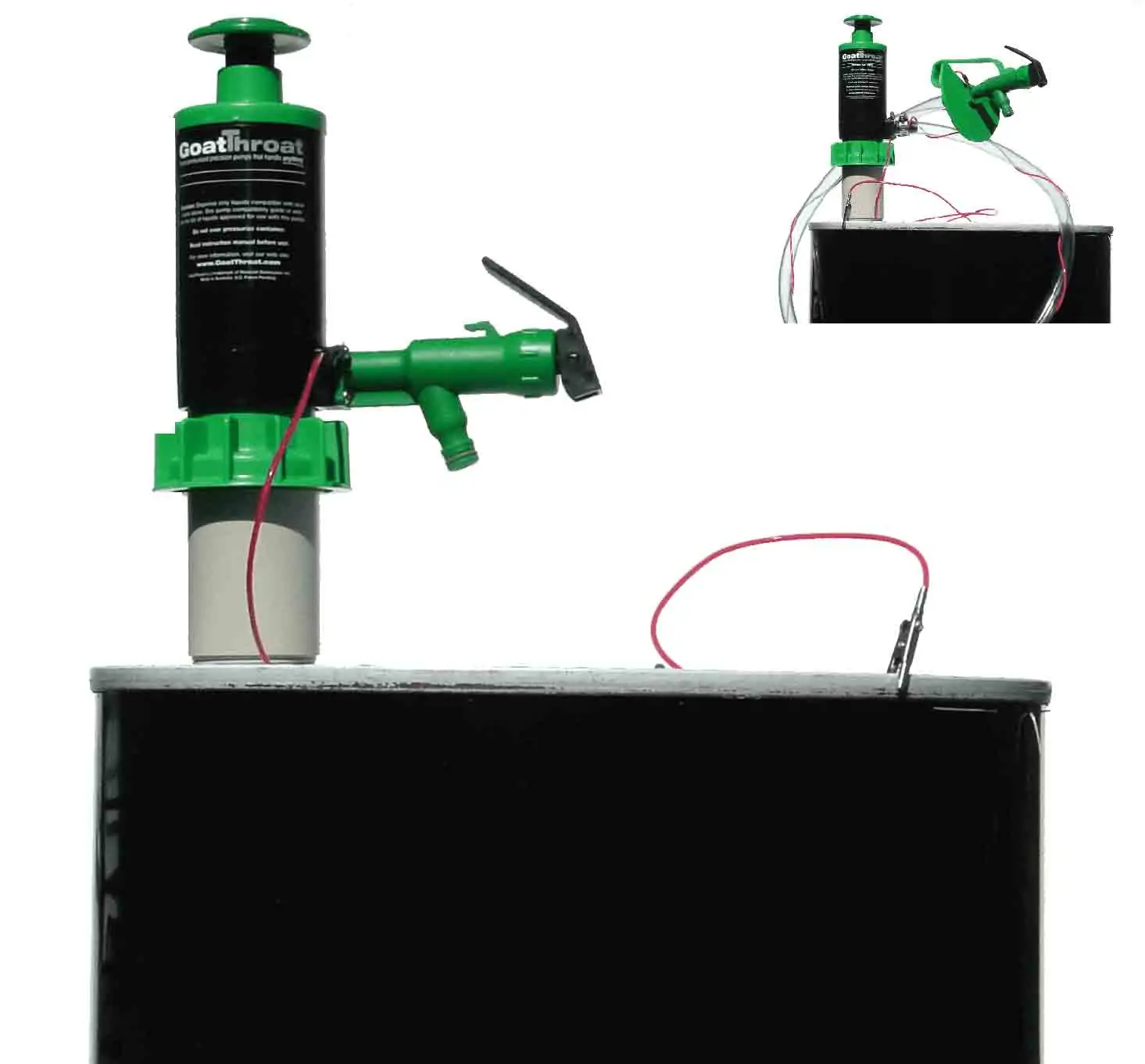

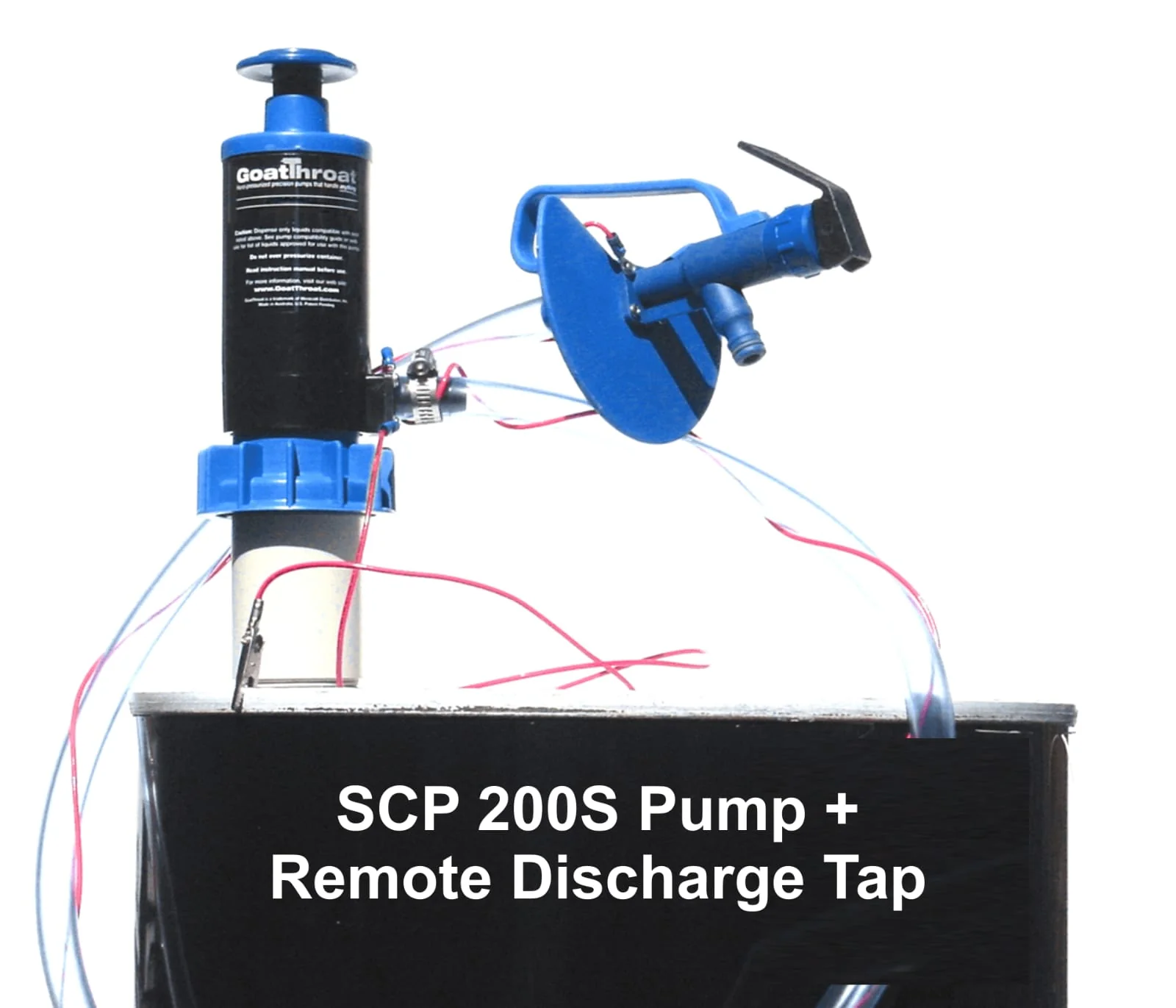

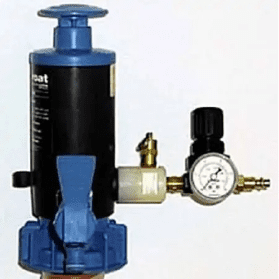

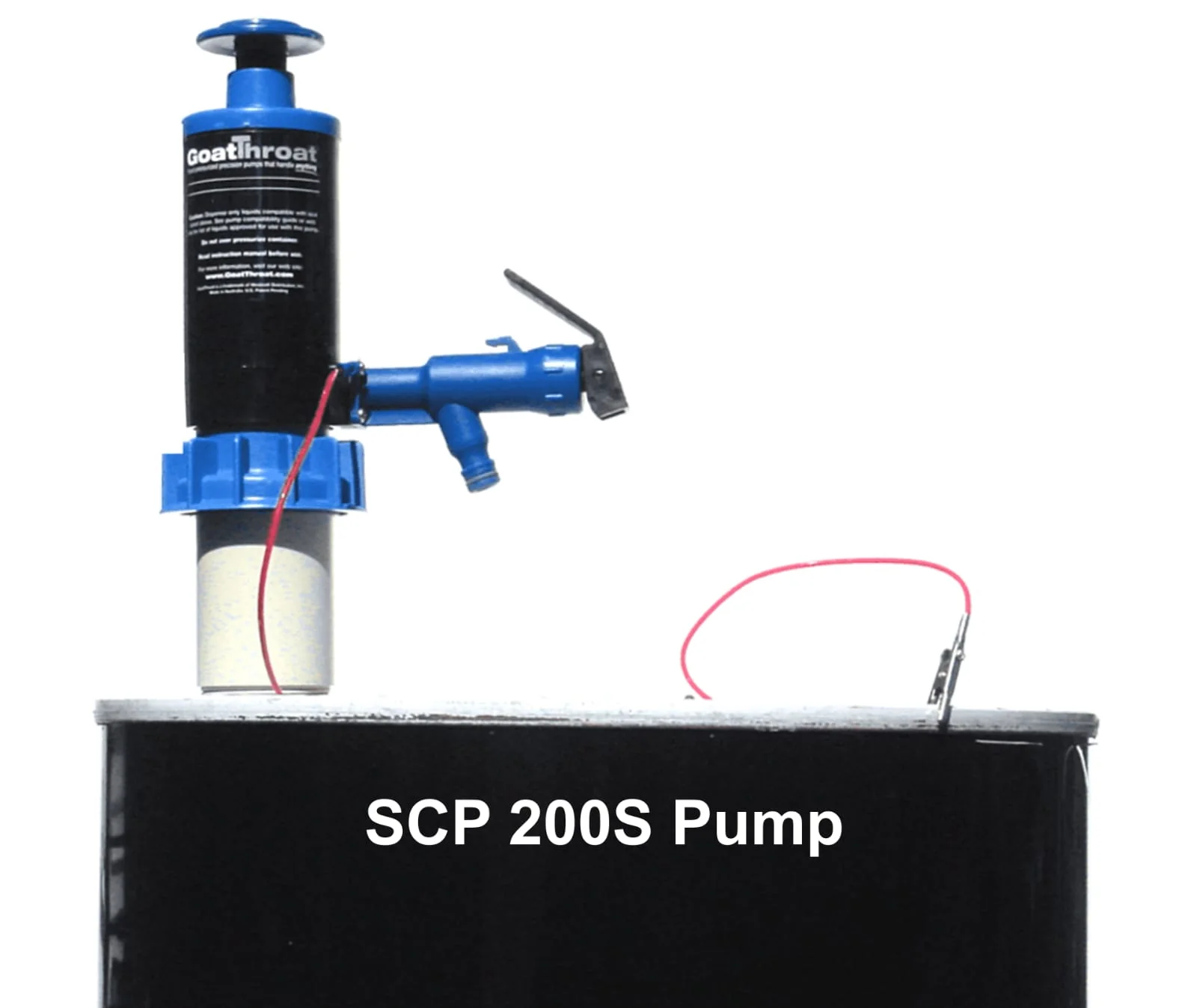

A food-grade barrel pump is a versatile tool that can be used for various applications, such as transferring liquids between containers, filling drums, or extracting samples for quality control purposes. Its ergonomic design ensures ease of use, with features such as a comfortable grip, adjustable flow control, and a lightweight structure. The pump can be easily connected to standard barrels and drums, making it a valuable asset for efficient liquid transfer operations.

What are the Benefits of FDA-Compliant Plastic?

The use of FDA-compliant plastic in the construction of a sanitary barrel pump offers several advantages! Firstly, it provides excellent chemical resistance, allowing the pump to handle a wide range of food and beverage products without the risk of contamination or degradation. Secondly, FDA-compliant plastic is non-toxic and imparts no taste or odor to the transferred liquids, preserving the integrity and quality of the final product. Additionally, this plastic is easy to clean, making maintenance a hassle-free process.

The Choice is Clear!

Investing in a sanitary food-grade barrel pump made with FDA-compliant plastic is crucial for ensuring the safety, quality, and efficiency of liquid transfer processes in the food and beverage industry. Its hygienic design, versatile functionality, and the use of FDA-compliant plastic make it an indispensable tool for businesses striving to meet and exceed food safety standards. By choosing a reliable barrel pump, companies can enhance their operations, protect their reputation, and prioritize the well-being of their customers.