Allergy Laboratories Inc., an FDA licensed pharmaceutical manufacturer of biological extracts for the diagnostic testing and therapeutic treatment of allergies, uses a sealed pump system to transfer acetone from 55 gallon drums to 1 gallon containers for a process to dry out pollen and mold.

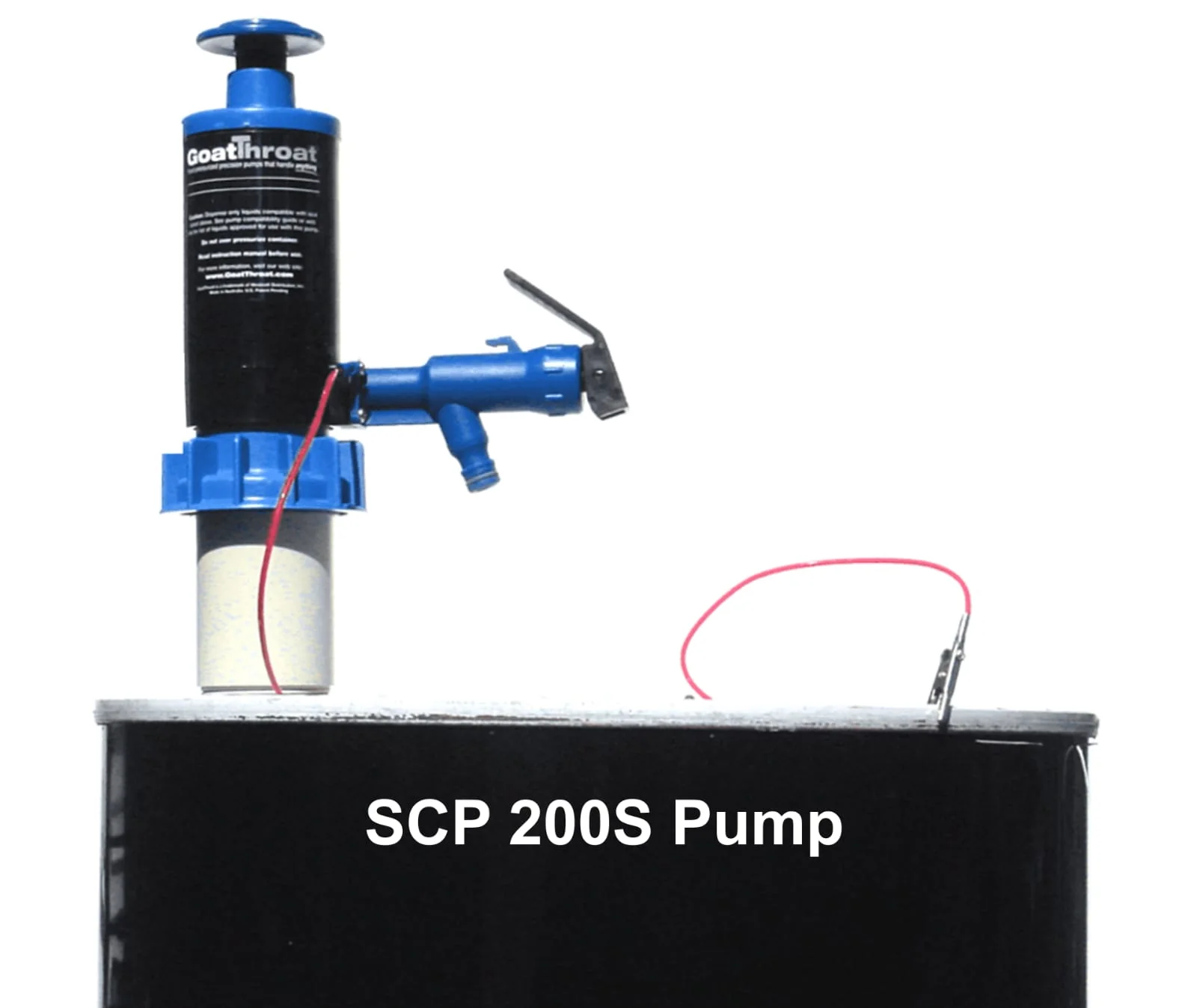

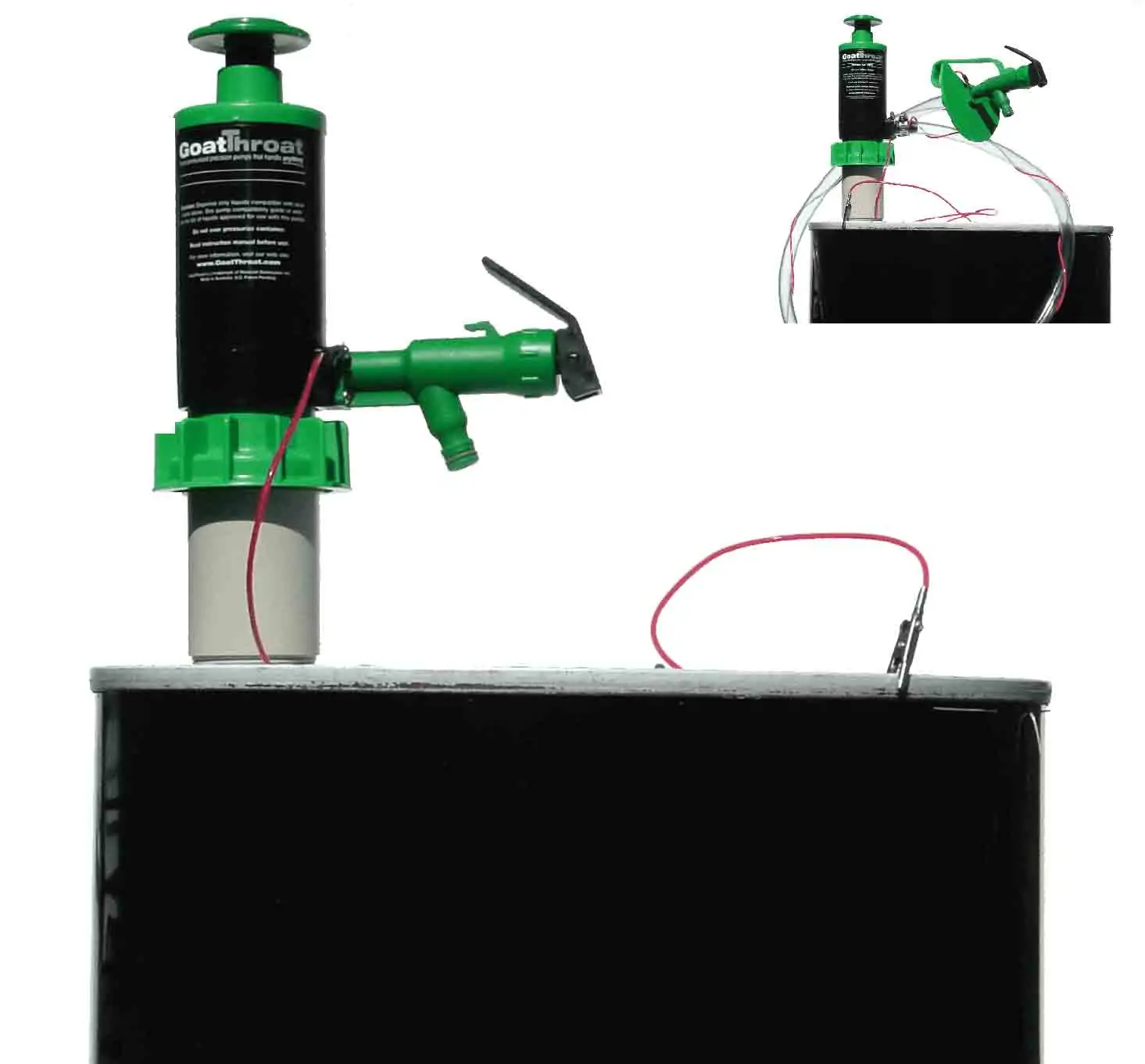

According to Charles Cheek, facility manager for Allergy Labs, the pharmaceutical chemical delivery process must be very clean and no foreign material can be introduced into the acetone. Because acetone is highly flammable, he was concerned about using an electric pump that could potentially create a spark. As a result, he decided to purchase a pump that had no electrical or moving parts that could create a hazard.

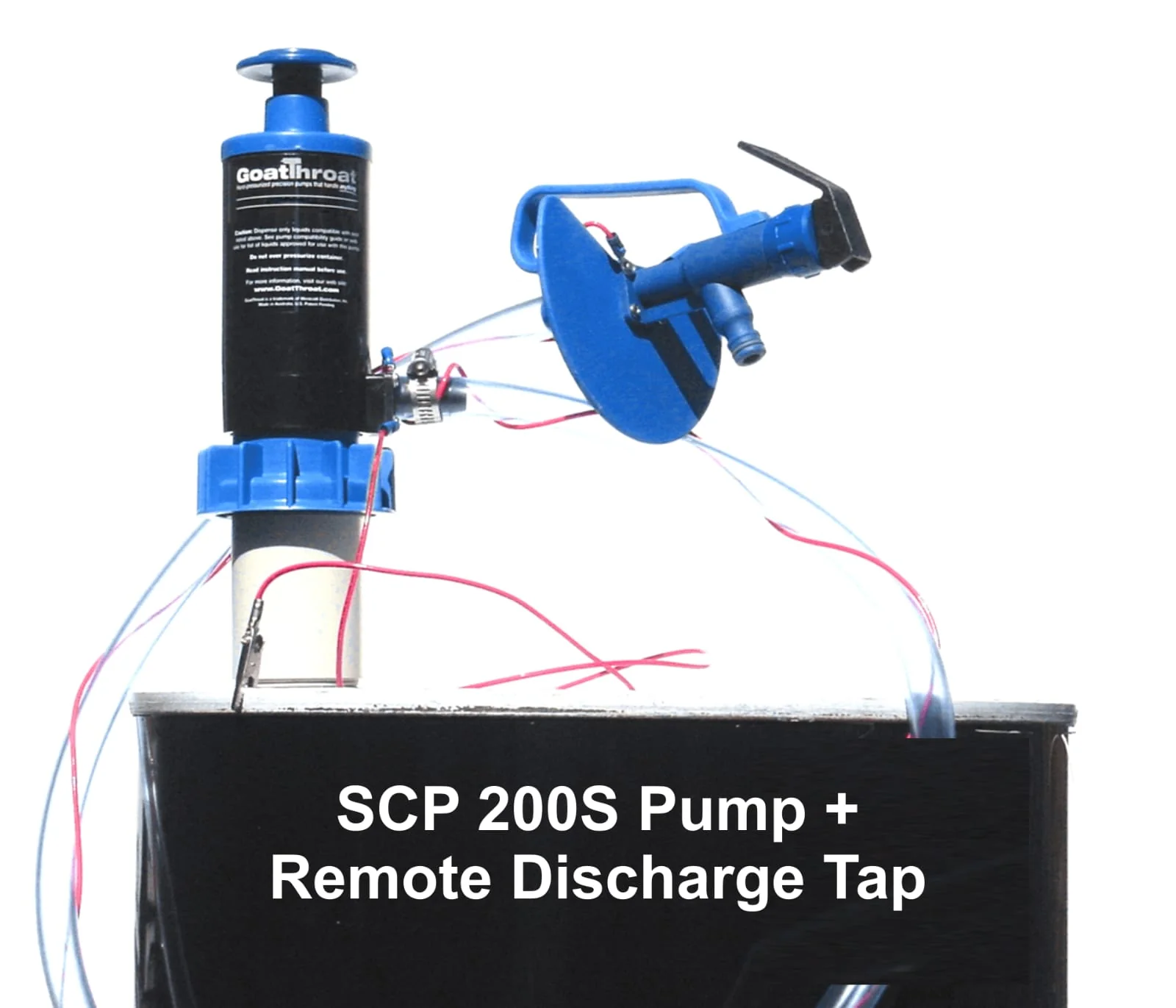

“We’ve found GoatThroat pumps to be a much safer way to transport chemical liquids,” says Cheek, who utilizes a pneumatic adaptor accessory to supply pressure via in‐house compressed air. “There is no spillage, splatter, overpouring, leaking, or VOCs because the system is self‐contained. There is no sprayback and we do not get chemicals on our hands. It is a nice, clean delivery system.”

Besides enhancing safety, Cheek says a sealed system can prevent loss of expensive chemicals like acetone. “I haven’t lost any product due to the pumps. They eliminate evaporation, do not leak or drip, and I can adjust the flow to get the exact amount I need without spilling or overflow.”

Cheek says he also utilizes pumps to transfer corrosive chemicals used to remove scale from several boilers. Previously, he had to fill a glass beaker with the chemical, climb a ladder and pour the chemicals into the top of the tank. Now, that work is performed with the help of the pump and 6’ extension hose accessory to efficiently deliver the cleaning chemicals. “Every time inspectors come in, they say we have the cleanest boiler they have seen,” says Cheek. “With this chemical transfer system, I’m able to transfer exactly what I need to get the job done.”

For more information, call 866‐639‐4628 (toll free)

Or visit www.GoatThroat.com