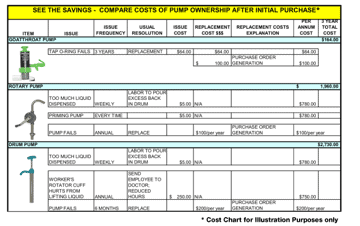

GoatThroat Pumps, hereafter referred to as GT Pumps, are known to offer the best cost savings and Return on Investment for any company which periodically transfers ounces to gallons of fluids, flammable or otherwise.

Companies spend hundreds if not thousands of dollars annua

GT Pumps provide totally safe and controlled delivery of chemicals through its engineered system. When chemicals cost hundreds of dollars a gallon, spills amount to hundreds a month and when recognized, the investment in a GT Pump is well made, paying for itself within a month or less. Hence it is easy to recognize the Return on this pump Investment. A further great payback is that these pumps are easily serviced, whereby a simple O-ring may be replaced after several years of operation; one user replaced the main plunger ring after 13 years of use, a documented fact. These pumps are not classed as Throwaway.

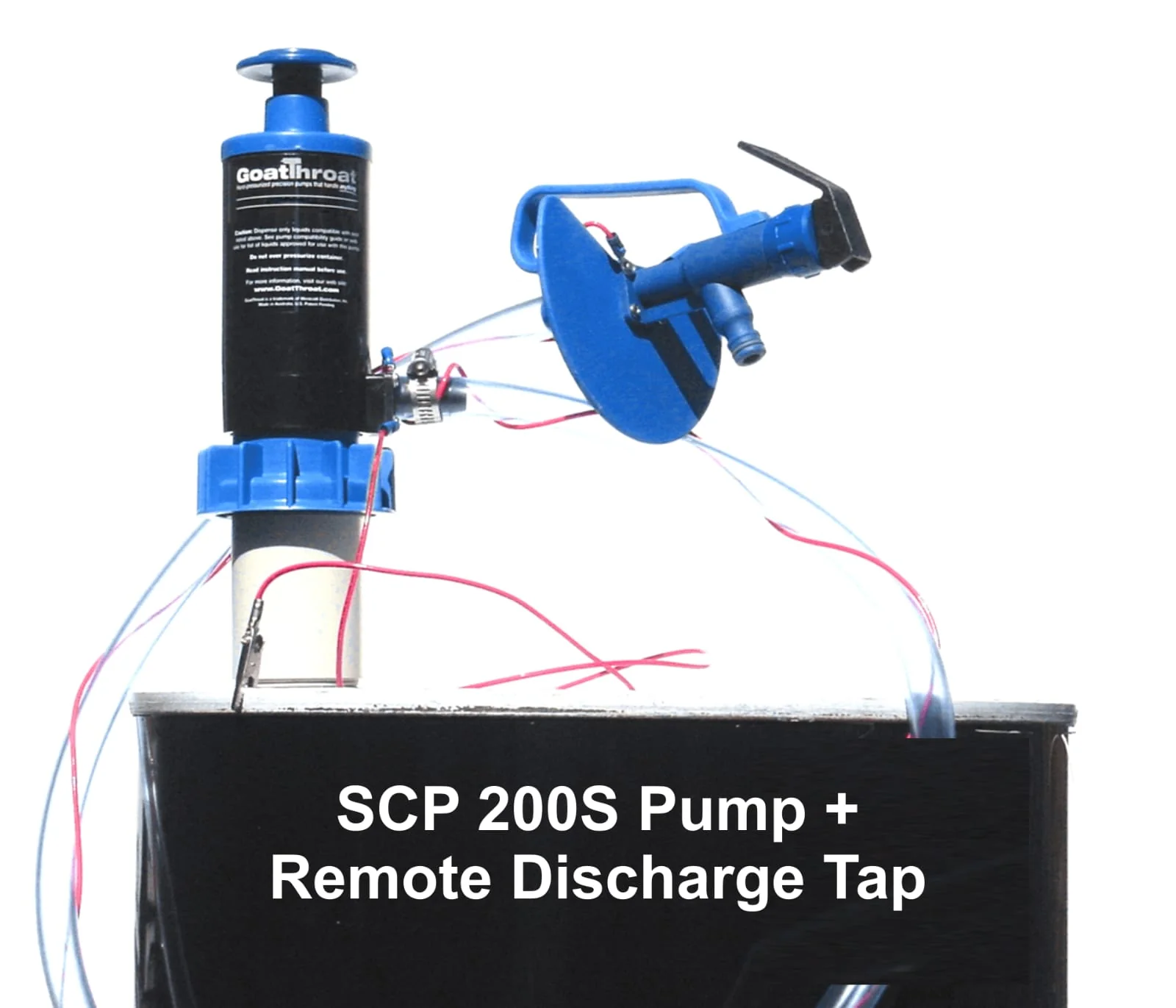

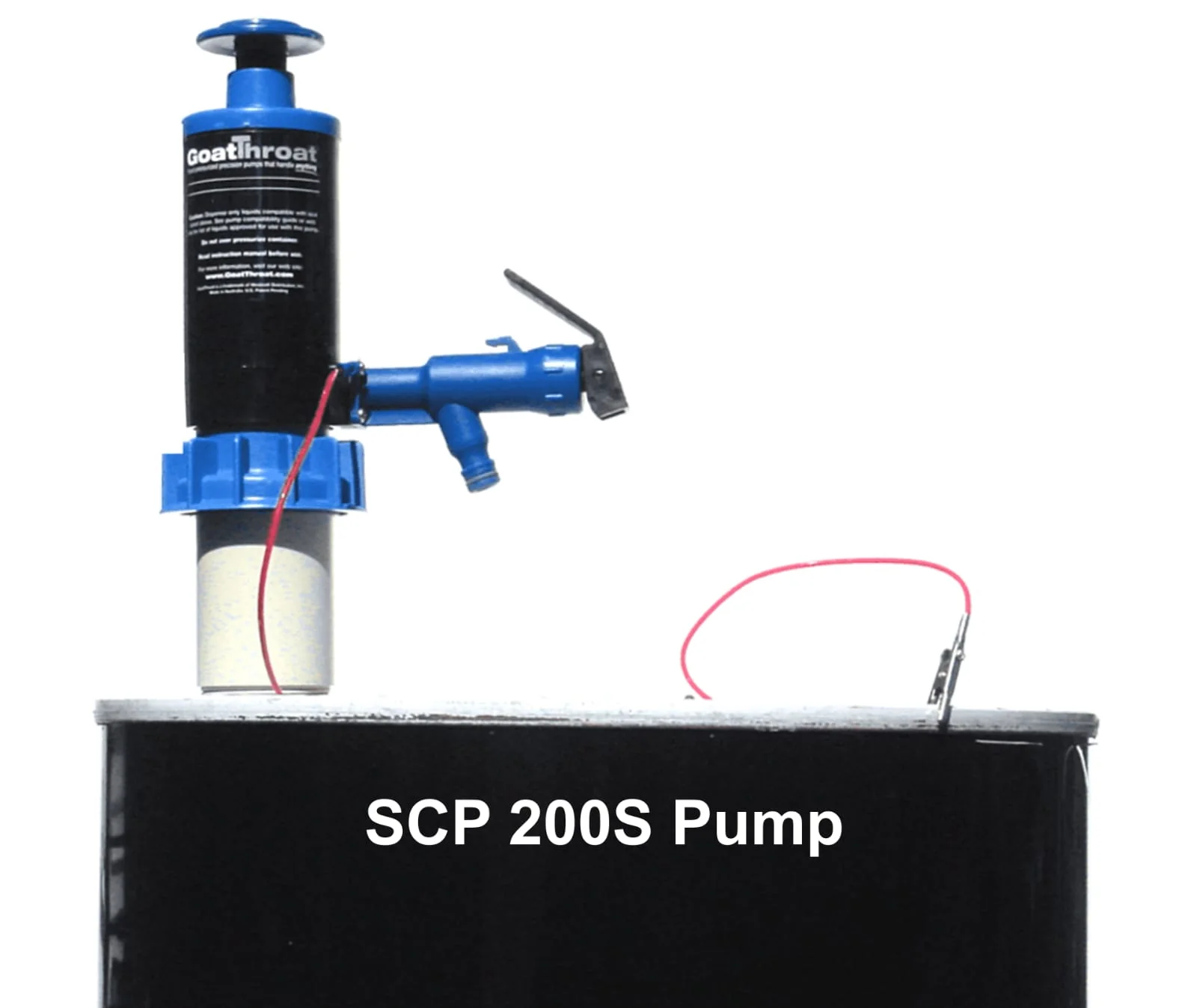

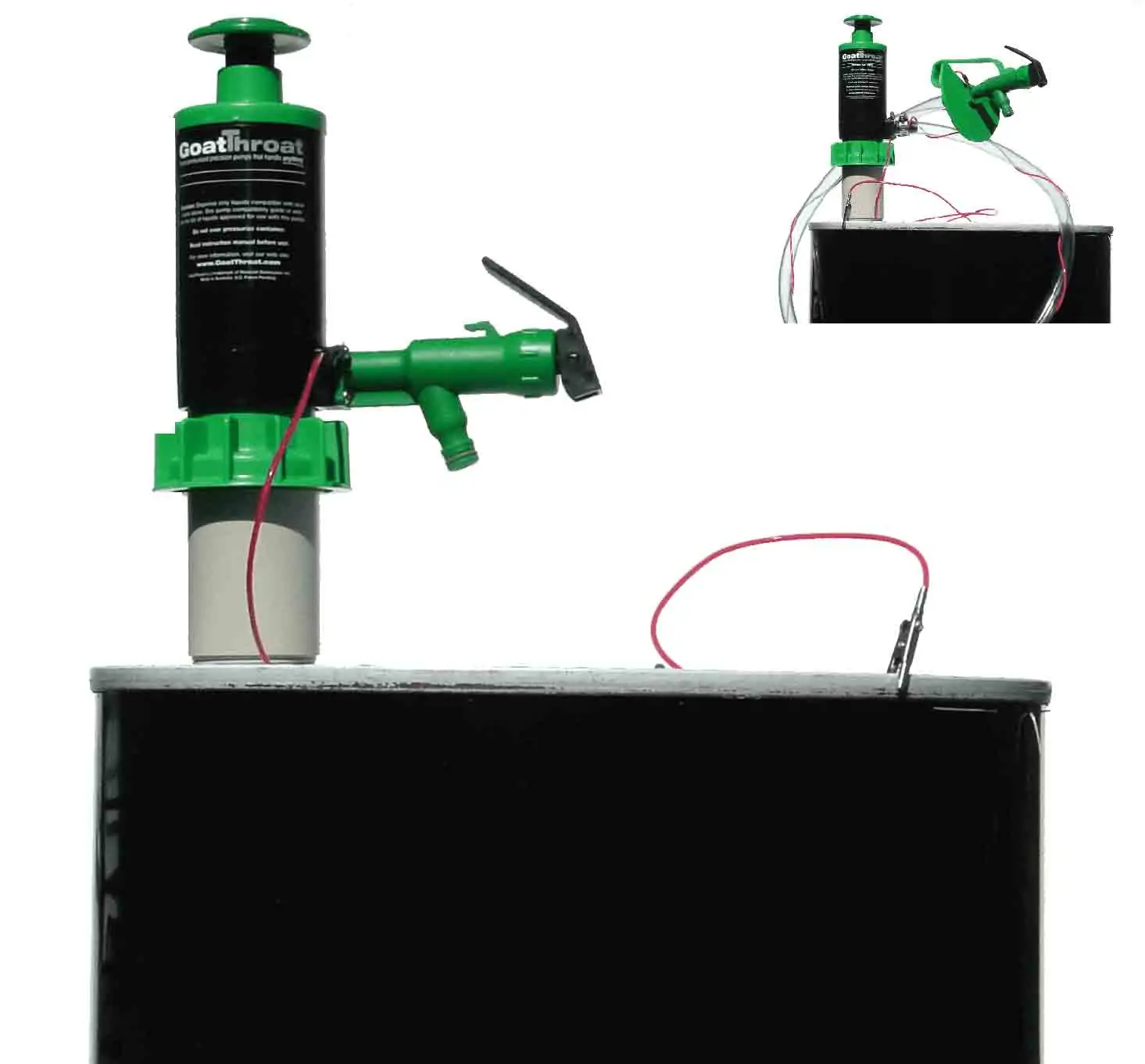

Other benefits from using GT Pumps include the elimination of Repetitive Motion Disorders. Such disorders cost thousands of dollars both in medical expenses as well as the loss of operator hours not working. These routinely occur with the use of traditional rotary pumps which require constant operation to keep the fluid flowing. GT Pumps only require infrequent hand operation which in fact may be eliminated by converting these pumps to a pneumatic state.

The term Best Practices has been given to GT Pumps by many users after realizing how the pumps operate and contribute to work place safety. Ease of use, controlled deliveries of chemicals, elimination of VOCs through the fact that the containers, 5 gallon pails to 55 gallon drums are all sealed; these are benefits contributing to the bottom line of companies. This sealed concept summarizes the benefits of GoatThroat Pumps. It should be noted that the insurance industry is now encouraging its clients to adopt the use of GT Pumps, as they contribute to improved worker safety significantly.