Agricultural Case Studies

Safe Chemical Handling Improves Bottom Line in Controlling Phytophthora Root Root

Rancho Rodoro, is a 40 acre avocado and lemon tree farm located in the Santa Clara River Valley of California. Owner Randall Axell divides his time between soil and pest management and improving crop production. Rancho Rodoro uses integrated practices which help to reduce Phytophthora Root Rot (PPR) spread.

Until recently, Axell has been using trunk injection of phosphoric acid just prior to the initiation of new root growth in May and August which is standard application methods for phosphites. Using PhosGrowTM by International Chemical Group which is registered in California as a fertilizer he recovered 6 acres of moderately diseased trees since 2004 and has a thriving avocado grove. While this method is very appropriate for moderate to severely diseased trees, it is overkill for control and disinfection of slightly diseased areas of the orchard.

Wanting to apply the phosphites via his existing irrigation system, Axell had trouble finding a transfer pump which would hold up to the acid and provide a safe solution for eliminate leaks and spills when moving the acid to the fertilizer tanks. He tried several pumps, none of which worked out. Finally he found GoatThroat Pumps.

“The GoatThroat pumps have adapters to fit all of my different containers,” states Axell. “We simply open up the tap and dispense a cup, a quart or a gallon depending on our need. This tool has improved the safety of our workers and helped us to be more compliant with local regulations. Because we have control of the amount of acid which is dispensed at one time, we are able to meet our HASSP requirements more easily. And our crop production is up 10 – 20% since 2004.”

Safety with Chemicals

Vineyards and Nurseries see big benefit to bottom line with safe chemical handling systems

The High Cost of Exposing Ag Workers to Chemicals at Point of Use

The tip-and-pour method, as well as poorly designed pumps, can expose workers to injury and companies to significant financial losses

Every day handlers and pesticide applicators transfer potentially hazardous chemicals and concentrates such as pesticides, herbicides, insecticides, fungicides, and liquid fertilizers from large drums into smaller containers or mixing tanks. However, this transfer process can have serious consequences if manual “tip-and-pour” techniques or poorly designed pumps are used.

Whether the chemicals are toxic, corrosive, or flammable, the danger of accidental contact can pose a severe hazard to workers. Some are even categorized as “Minimal Exposure Pesticides” (MEPs), (Is this a US nomencalture? I have not heard of it before – all referencess on google seem to be for China) including commonly used items such as Buctril, Inject-A-Cide, Omite and Comite that can cause physical harm that may not be noticed until later. (I am not sure targeting these chemicals is a good idea especially if we are looking to establish relations with their manufacturers)

In fact, each year 1,800-3,000 ( this number seems low) preventable occupational incidents involving pesticide exposure are reported Keeping workers safe is not just a best management practice, it is the law. The federal Worker Protection Standard (WPS) was revised in 2015 and now provides a greater focus on reducing pesticide exposures. A closed system of transferring chemicals reduces unnecessary exposures by providing controlled delivery of chemical products without fear of worker exposure, over-pouring, spilling, or releasing vapors. Many of the revisions became effective this January.

“Ag pesticide toxicity and corrosiveness are the main dangers, but even organic pesticides can be harmful if there is exposure,” says Kerry Richards, PhD, President Elect of the American Pesticide Association of Pesticide Safety Educators and former Director of Penn State’s Pesticide Safety Education Program. “Some of the non-synthetic (organic) chemicals are a particular contact risk if they are corrosive.”

In addition to the potential for injury, there can also be serious financial ramifications for the grower or ag product manufacturing facility if pesticides or liquid chemicals spill.

“Beyond workers compensation, there can be huge potential liability, EPA or state regulatory fines, as well as clean-up or remediation costs,” says Richards. “This is particularly true if a pesticide gets into a water source, kills fish, or contaminates drinking water.”

Spiraling Costs of Lost Containment

Richards, who works with the National Pesticide Safety Education Center and has over 30 years of pesticide safety education experience, says “Exposure risk is highest for those loading chemicals into mix tanks because it is more concentrated and hazardous before diluted with water. Any time you lose containment, the risks can be serious and spiral out of control.”

Corrosive chemicals, for example, can severely burn skin or eyes, and many chemical pesticides are toxic when touched or inhaled. “One synthetic herbicide is so highly acidic that it bleaches out the chloroform in plants and kills them,” says Richards. “If you splash it in your eye, you will burn out your cornea.”

Some chemicals are flammable as well, and if not properly handled and contained, can be ignited by sparking from nearby motors or mechanical equipment. The danger of a fire spreading can be serious both in the field and at ag product manufacturing facilities.

In addition to the cost of cleanup or treating injuries, substantial indirect costs can also be incurred. These include supervisors’ time to document the incident and respond to any added government inspection or scrutiny, as well as the potential for slowed grower production or even a temporary shutdown at ag manufacturing plants.

“The direct and indirect costs of a pesticide spill or injury can be substantial, not the least of which is the loss of wasted chemicals,” says Richards. “Pesticides, particularly newer concentrated formulations, are very expensive so spilling a few ounces could cost you several hundred dollars in lost product during a single transfer.”

Chemical Transfer Techniques

Traditional practices of transferring liquid chemicals suffer from a number of drawbacks.

Manual techniques, such as the tip-and-pour method, are still common today. Tipping heavy barrels or even 2.5 G containers, however, can lead to a loss of control and over pouring.

“Some growers choose to transfer chemicals manually, but it is very difficult to control heavy drums,” cautions Richards. “I’d advise against it because the risk of a spill is so high, and it can lead to back injury or muscle strain as well.”

Although a number of pump types exist for chemical transfer (rotary, siphon, lever-action, piston and electric), most are not engineered as a sealed, contained system. In addition, these pumps can have seals that leak, are known to wear out quickly, and can be difficult to operate, making precise volume control and dispensing difficult.

In contrast, closed systems can dramatically improve the safety and efficiency of chemical transfer. California’s Department of Pesticide Regulation, in fact, requires a closed system for mixing and so handlers are not directly exposed to the pesticide.

“Either A closed, or a sealed system is ideal for handling pesticides or other dangerous chemicals, and is becoming a best practice technique,” says Richards. “With such devices, like GoatThroat Pumps, you can maintain a controlled containment from one vessel to another that limits any potential exposure.”

A sealed system delivers liquids to an intermediate measuring device and is useful for low toxicity liquids. A closed system moves the material from point A to Point B without leaking or causing exposure to the handler through hoses using dry-break fittings on the connection points means no applicator exposure and helps guarantee safety. Liquids are transferred from the source container, into the measuring system, and then to the mix tank.

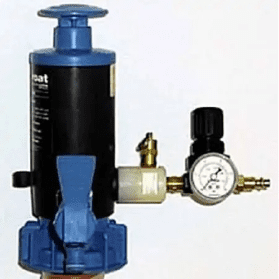

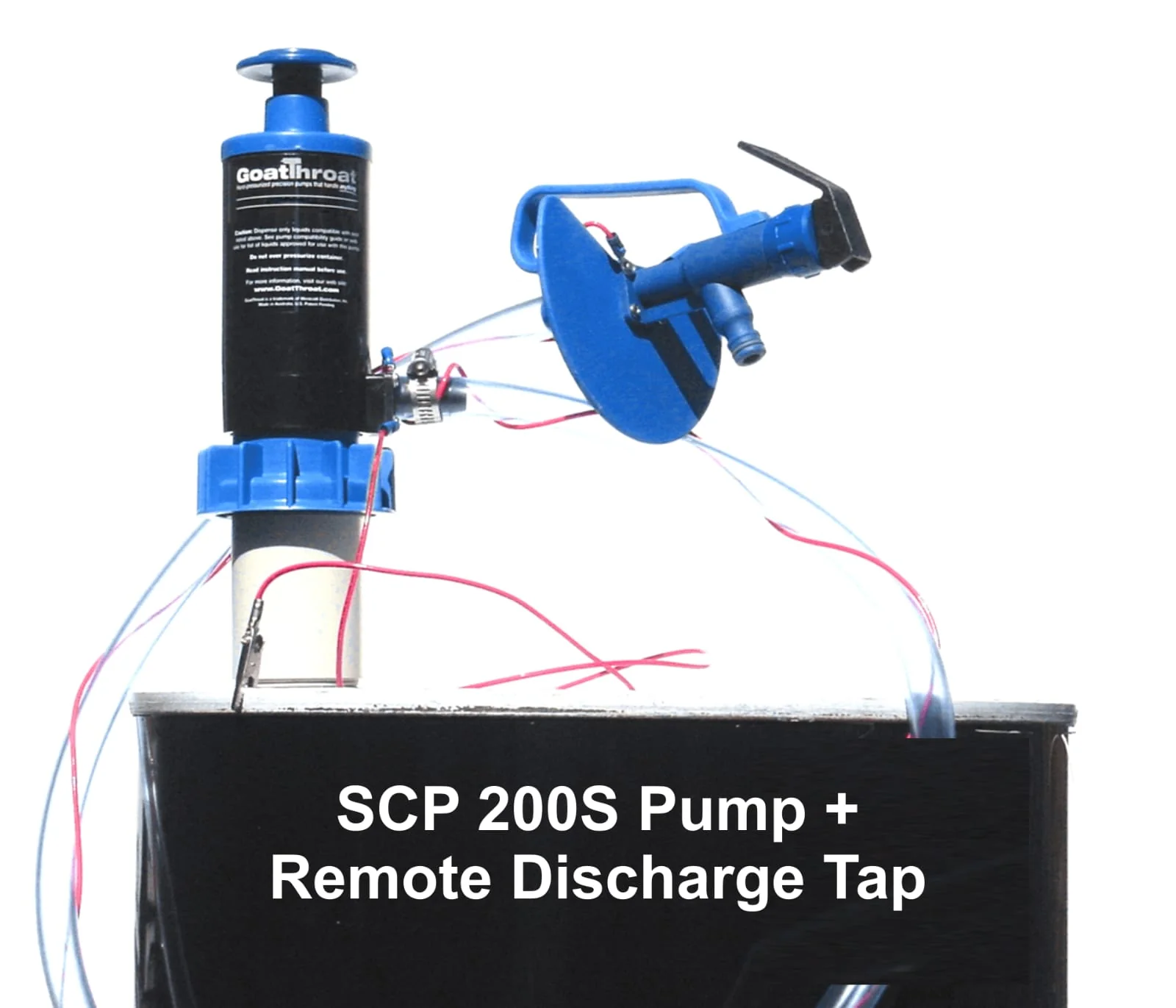

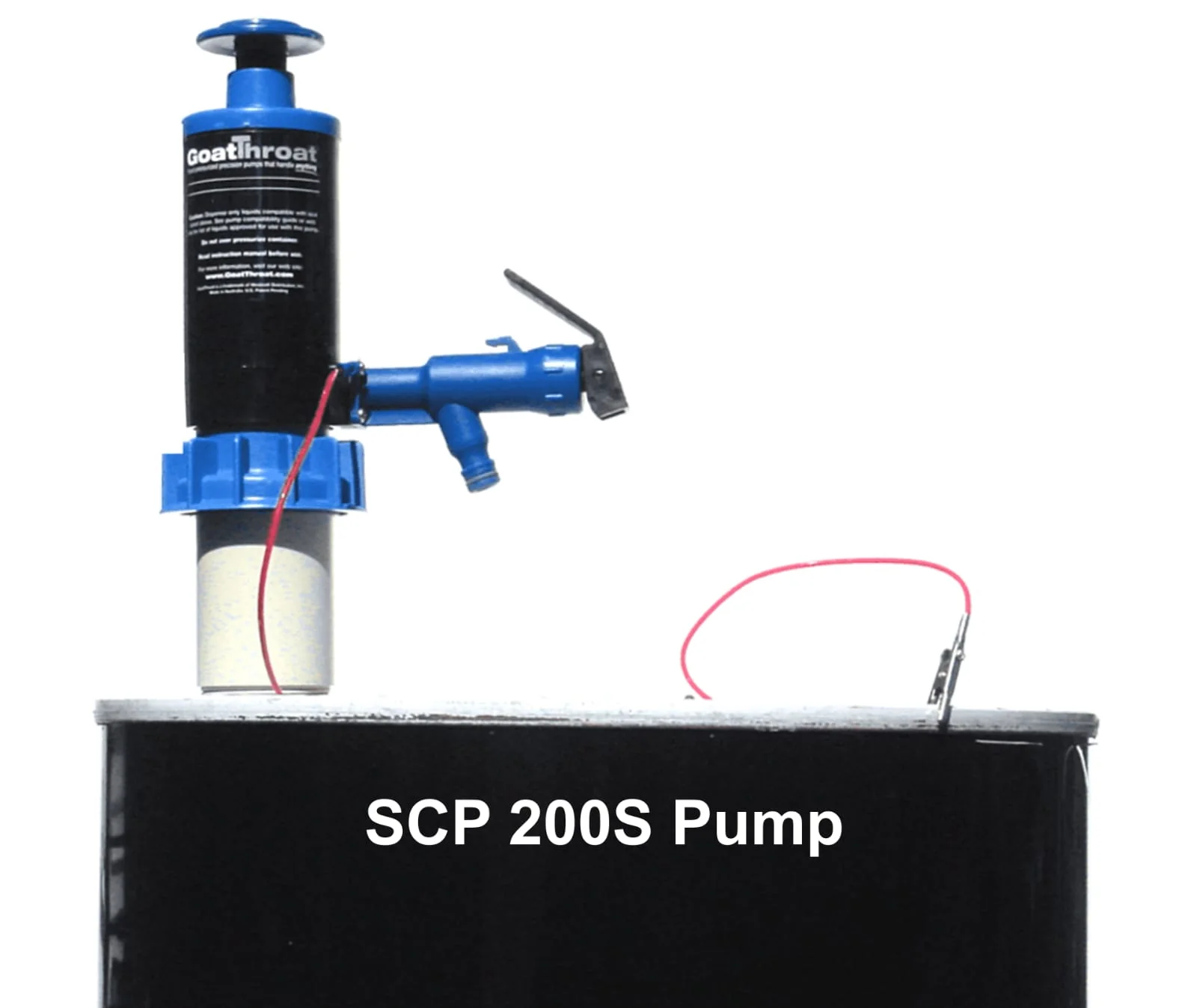

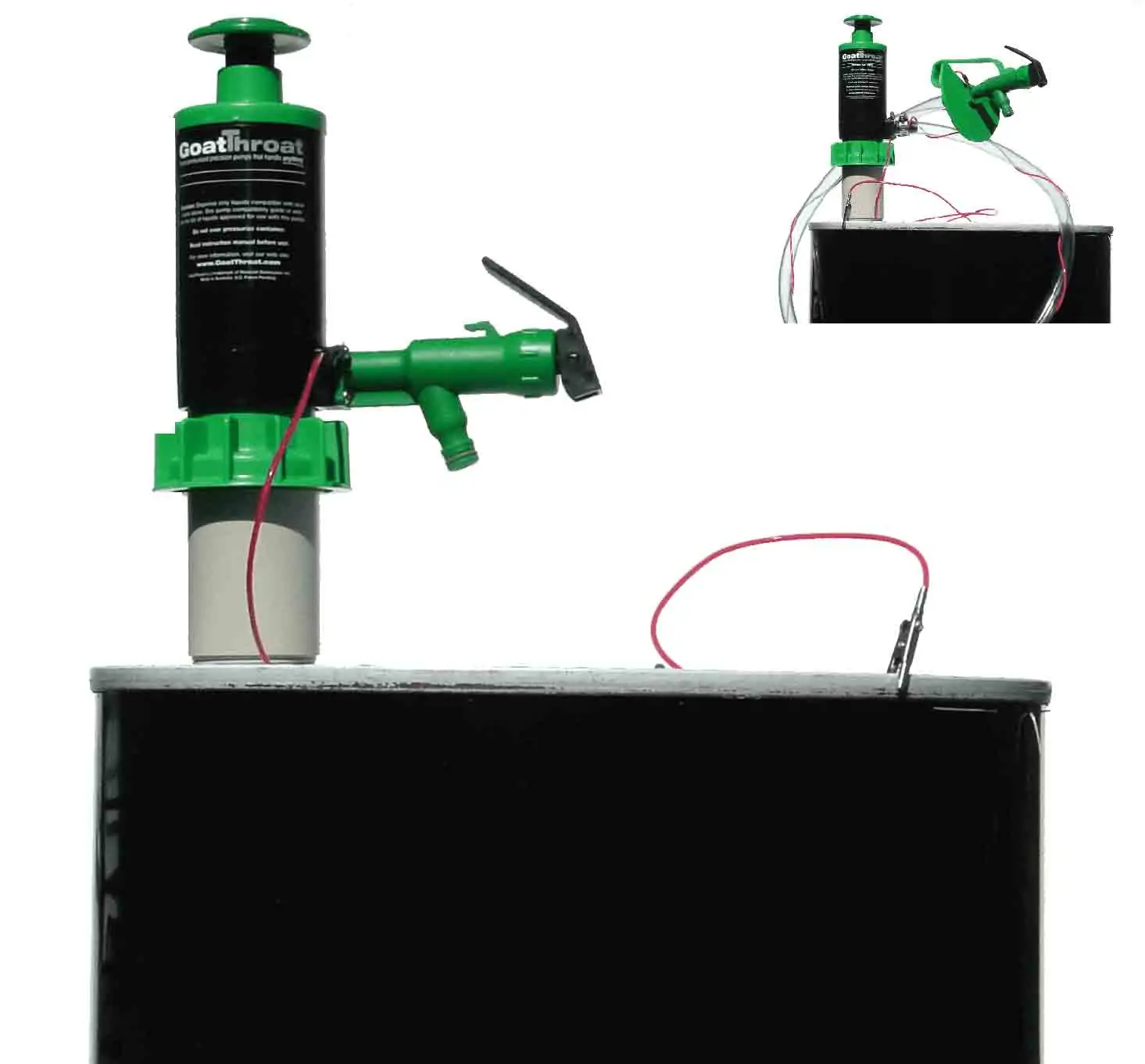

Small, versatile, hand-operated pressure pumps, such as those manufactured by GoatThroat Pumps, are engineered to work as a system which can be either closed or sealed. The pumps can be used for the safe transfer of over 1400 industrial chemicals, including the most aggressive pesticides.

These pumps function essentially like a beer tap. The operator attaches the pump, presses the plunger several times to build up a low amount of internal pressure, and then dispenses the liquid. The device is configured to provide precise control over the fluid delivery, from slow (1ML/ 1 oz.) up to 4.5 gallons per minute, depending on viscosity.

Because such pumps use very low pressure (<6 PSI) to transfer fluids through the line and contain automatic pressure relief valves, they are safe to use with virtually any container from 2-gallon jugs to 55-gallon drums.

Ricci Vineyards Adopts “Best Practice” Pump Systems

When Jon DiPiero managed Ricci Vineyards, a small wine grape vineyard in Sonoma, CA, he sought a safer, more efficient way to transfer pesticides for mixing and spraying that complied with the state’s closed system requirement for MEPs. Once again this word

“We had to fill 2.5 gallon containers from a 55 gallon drum,” says DiPiero. “Traditional tipping and pouring from a drum wasn’t going to work due to the potential for spills, splashes, over pouring and chemical exposure, as well as the state mandate for a closed system for some pesticides.”

DiPiero turned to GoatThroat Pumps and was happy with the results for a number of reasons.

“Because the pump is closed, sealed, and allows containers to remain in an upright position, it complied with state regulation and virtually eliminated the potential for all forms of chemical exposure,” says DiPiero.

Piero says the air pressure supplied by the hand pump allows the precise flow required into a measuring cylinder.

In case of overfill, Piero says, “The operator can open a valve to release air pressure and the pesticide will backflow into the tank with no cross contamination. This gave us the exact amount we needed so there was no waste.”

According to DiPiero, a multi directional spray attachment also enables rinsing of every corner of container without having to pour into it and shake it. He says this helps to minimize exposure when cleaning a container for reuse and satisfies California “triple rinsing” requirements.

“Whether for pesticides, herbicides, fungicides, or liquid fertilizers, a closed and sealed pump design could help with the safe production or mixing of any liquid chemical,” says DiPiero.

Safe Chemical Handling at Lancaster Farms

When Lancaster Farms, a wholesale container plant nursery serving the Mid-Atlantic and New England regions, required a higher chemical pH to adjust its well water for a pesticide spray application, it had to transfer acid to buffer the spray water.

According to Shawn Jones, Lancaster Farms’ Propagation and Research Manager, for bulk cost savings, the nursery chose to purchase 55 gallon drums of sulfuric acid to raise chemical pH. However, Jones was wary of the danger that tipping and pouring acid from the drums would pose, along with pouring bleach and another strong disinfectant for a different use in the propagation area.

“We use 40% sulfuric acid to buffer our spray water,” says Jones. “Our water is recycled, with some storage areas relatively close to our water source, so wanted to avoid any possibility of accidental spillage.”

Previously, the nursery had used siphon pumps to transfer the acid, bleach, and disinfectant, but Jones was dissatisfied with this approach. “None of our siphon pumps lasted more than six months before we had to replace them, and none allowed metering with the kind of precision we required,” he says.

Instead, Jones chose to implement several closed, sealed GoatThroat Pumps, along with graduated cylinder attachments for precise measurement. “With the pumps, the drums always remain in an upright position so they won’t tip over accidentally,” says Jones. “We get precise measurement into our mix tanks. We use every drop, spill nothing, and waste nothing.”

In terms of longevity, Jones’ first closed, sealed pump has already lasted six years and outlasted a dozen previous siphon pumps.

“Our GoatThroat Pumps paid for themselves in safety and savings our first growing season, and should last a decade or more with just routine maintenance or repair,” concludes Jones. “Any grower, farmer, or nursery that needs to move or measure dangerous liquids safely and reliably should consider one.”

Agricultural chemicals are very expensive, and growers are always looking for ways to decrease the cost of inputs to help increase profits. Sealed systems and closed systems allow for accurate and precise measuring of chemicals, which ensures that you’re using only the amount of product required and not one extra drop. Taking the guesswork out of measuring costly materials, and providing an efficient means of transferring custom blended or dilute products from original containers to mix tanks or back pack sprayers cuts input costs. This keeps expenses to a minimum, with the important bonus of increasing the safety of handlers by reducing the potential exposure to the chemical, which helps increase the bottom line and can assist with Worker Protection Standard regulatory compliance.

For more info: call 866-639-4628 toll free; Fax: 212-243-6070; E-mail info@goatthroat.com; or write to Westcott Distribution, Inc. 60 Shell Avenue Milford, CT 06460.