Search Results for: Drum Pumps

Industrial Manufacturing Drum Pumps

Recommended by numerous chemical companies, there is no doubt that GoatThroat® Pumps improve safety and reliability. Users all agree that spill prevention beats clean up. With the cost of chemicals, companies use GT Pumps because they are safe for use with over 1300 chemicals, and meet exacting requirements. GoatThroat Pumps offers 2 metering systems for data collection in support of required annual emissions reporting for EPA’s Air Inventory Reporting, Toxic Release Inventory (TRI), Pollution Prevention (P2) and Greenhouse Gasses (GHG). Developed for a Federal Government Agency for point-of-use chemical delivery, the systems also substantially reduce fugitive air emissions, prevents chemical spills and mitigate worker exposure to hazardous liquids and emissions. The GT-M-N and the GT-M-K have different meters which are matched to the liquids for compatibility. These systems can be added to any existing GoatThroat Pump System or factory installed on a new system. GT pumps typically have a service life of 10 to 15 years; and provide for spill-proof, safe transfer, virtually emission-free transfer of over 1500 fluids and solvents. RoHS compliant, these food grade products are designed to drain containers dry, making them Resource Conservation and Recovery Act (RCRA) empty. They also meet UN safety standards, helping customers meet compliance and environmental requirements.

substantially reduce fugitive air emissions, prevents chemical spills and mitigate worker exposure to hazardous liquids and emissions. The GT-M-N and the GT-M-K have different meters which are matched to the liquids for compatibility. These systems can be added to any existing GoatThroat Pump System or factory installed on a new system. GT pumps typically have a service life of 10 to 15 years; and provide for spill-proof, safe transfer, virtually emission-free transfer of over 1500 fluids and solvents. RoHS compliant, these food grade products are designed to drain containers dry, making them Resource Conservation and Recovery Act (RCRA) empty. They also meet UN safety standards, helping customers meet compliance and environmental requirements.Pharmaceutical & Medical Drum Pumps

Recommended by several chemical companies, there is no doubt that GoatThroat® Pumps improve reliability and safety in pharmaceutical manufacturing environments. Users all agree that spill prevention beats clean up with solvents, acids, and other corrosives. With the cost of chemicals, many facilities use GT Pumps because they are safe for contact with over 1700 chemicals and meet exacting requirements. The sealed system is essential in such environments because it reduces vapors and emissions and allows for complete control over the volume of liquids dispensed. The SCP Line of Pumps which are made of static conductive plastic allows these pumps to be used with flammable liquids meeting both NFPA 77 and NFPA 30 requirements. All non-SCP pumps are made from Food Grade materials making them safe for food contact.University Lab Drum Pumps

Recommended by several chemical companies, there is no doubt that GoatThroat® Pumps improve reliability and safety in University environments. Users all agree that spill prevention beats clean up with solvents, acids, and other corrosives. With the cost of chemicals, many facilities use GT Pumps because they are safe for contact with over 1700 chemicals and meet exacting requirements. The sealed system is essential in such environments because it reduces vapors and emissions and allows for complete control over the volume of liquids dispensed. The SCP Line of Pumps which are made of static conductive plastic allows these pumps to be used with flammable liquids meeting both NFPA 77 and NFPA 30 requirements. All non-SCP pumps are made from Food Grade materials making them safe for food contact. GoatThroat Pump’s unique technology help companies reduce hazmat incidents and save money at their facilities by preventing costly chemical spills and the associated cost of reporting and downtime. The systems mitigate worker compensation claims by preventing workers exposure to hazardous chemicals and by eliminating repetitive motion and other injuries.Food Grade Pumps

Recommended by several ingredient companies and chemical companies, there is no doubt that GoatThroat® Pumps improve reliability and safety. Users all agree that spill prevention beats clean up. With the cost of ingredients, many food manufacturers use GT Pumps because they are safe for food contact and meet exacting requirements. They are also perfect for sanitation chemicals and offer a 10 year life expectancy.Automotive Hand Pumps

Ideal for auto repair and fleet management facilities, GoatThroat Pumps are safe for use with more than 1200 liquids -- including DEF, coolants, windshield washing fluids, gasoline, diesel fuel, additives, lubricants and transmission fluids. Suitable for viscosities up 270 CP, 1400 SSU, 300 CS. Synthetic oils and oils which incorporate solvents will use the GT300 with Viton seals. The pneumatic adapter will work with your air system. A few strokes of the plunger pressurizes the container, and liquids can be dispensed with one touch of the tap, as easily as opening and closing a faucet. Precise flow control helps conserve inventory by eliminating the guesswork from dispensing and measuring precise amounts of liquids. Automotive Applications:- Transferring fuel, lubricants, brake and transmission fluids to vehicles

- Decanting and applying cleaners and degreasers

- Mixing fuels with precise amounts of additives without drips or spills

- Pressurized liquids can be easily transferred to levels up to 6 feet higher than the container, which is impossible with traditional gravity-fed liquid transfer methods.

Pumps for DEF

Because the purity of Diesel Exhaust Fluid is essential to performance, GoatThroat® offers DEF handling solutions that maintain purity of DEF while delivering superior performance at an affordable price. A few strokes of this mobile chemical pump allows for smooth and safe dispensing of DEF at up to 3 – 4 gallons GPM with only 4 psig. A BGA Pneumatic Adapter can be added so that DEF is always available without recharging the drum by hand. The equipment listed here complies with the ISO standards for proper handling of DEF. Unique Made in the USA, our DEF handling systems work with the variety of DEF containers offered in today’s market. Click an image to enlarge… [gallery columns="2" link="file" ids="4342,4341,4340,4339"]Golf Course and Landscape Pumps

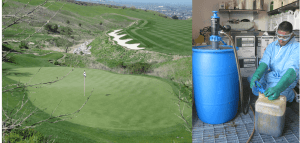

Recommended and used by several herbicide companies, there is no doubt that GoatThroat Pumps improve safety and reliability. Users all agree that spill prevention beats clean up. With the cost of chemicals, many golf and landcare professionals use GT Pumps because they are durable with herbicides, fungicides, wetting agents and fertilizers. With the extended life expectancy and durability, they pay for themselves the first year. 5 years later, you will forget the mess your chemical room used to be. And your workers will be safer with fewer accidents. [gallery link="file" columns="2" ids="4496,4497"]Electronic Manufacturing Pumps

Recommended by several chemical companies, there is no doubt that GoatThroat® Pumps improve reliability and safety in electronics manufacturing environments. Users all agree that spill prevention beats clean up with solvents, acids, and other corrosives. With the cost of chemicals, many facilities use GT Pumps because they are safe for contact with over 1700 chemicals and meet exacting requirements. The sealed system is essential in such environments because it reduces vapors and emissions and allows for complete control over the volume of liquids dispensed. The SCP Line of Pumps which are made of static conductive plastic allows these pumps to be used with flammable liquids meeting both NFPA 77 and NFPA 30 requirements. All non-SCP pumps are made from Food Grade materials making them safe for food contact. GoatThroat Pump’s unique technology help companies reduce hazmat incidents and save money at their facilities by preventing costly chemical spills and the associated cost of reporting and downtime. The systems mitigate worker compensation claims by preventing workers exposure to hazardous chemicals and by eliminating repetitive motion and other injuries.Laboratory, R&D Testing Pumps

Recommended by several chemical companies and chemical companies, there is no doubt that GoatThroat® Pumps improve reliability and safety. Users all agree that spill prevention beats clean up. With the cost of chemicals, many laboratories use GT Pumps because they are safe for contact with over 1200 chemicals and meet exacting requirements. This maintenance-free, environmentally sound, chemical drum pump allows fast safe transfer of chemicals from nearly any container from 5-gallon pails to 55-gallon drums. Patented leak-proof design conserves inventory, keeps work areas clean and prevents potentially hazardous spills. And unlike expensive electrical pumps, GoatThroat Pumps cost less, require no power, and create no potential sparking hazard.

Chemical Handling Pumps

[caption id="attachment_4491" align="alignleft" width="300"] GoatThroat in action at Ridgeway Industries[/caption]

Recommended by several chemical companies, there is no doubt that GoatThroat® Pumps improve reliability and safety in chemical manufacturing environments. Users all agree that spill prevention beats clean up with solvents, acids, and other corrosives. With the cost of chemicals, many facilities use GT Pumps because they are safe for contact with over 1700 chemicals and meet exacting requirements. The sealed system is essential in such environments because it reduces vapors and emissions and allows for complete control over the volume of liquids dispensed. The SCP Line of Pumps which are made of static conductive plastic allows these pumps to be used with flammable liquids meeting both NFPA 77 and NFPA 30 requirements. All non-SCP pumps are made from Food Grade materials making them safe for food contact. GoatThroat Pump’s unique technology help companies reduce hazmat incidents and save money at their facilities by preventing costly chemical spills and the associated cost of reporting and downtime. The systems mitigate worker compensation claims by preventing workers exposure to hazardous chemicals and by eliminating repetitive motion and other injuries.

GoatThroat in action at Ridgeway Industries[/caption]

Recommended by several chemical companies, there is no doubt that GoatThroat® Pumps improve reliability and safety in chemical manufacturing environments. Users all agree that spill prevention beats clean up with solvents, acids, and other corrosives. With the cost of chemicals, many facilities use GT Pumps because they are safe for contact with over 1700 chemicals and meet exacting requirements. The sealed system is essential in such environments because it reduces vapors and emissions and allows for complete control over the volume of liquids dispensed. The SCP Line of Pumps which are made of static conductive plastic allows these pumps to be used with flammable liquids meeting both NFPA 77 and NFPA 30 requirements. All non-SCP pumps are made from Food Grade materials making them safe for food contact. GoatThroat Pump’s unique technology help companies reduce hazmat incidents and save money at their facilities by preventing costly chemical spills and the associated cost of reporting and downtime. The systems mitigate worker compensation claims by preventing workers exposure to hazardous chemicals and by eliminating repetitive motion and other injuries.About Us

Who we are and what we do

At GoatThroat Pumps, there is no compromise in terms of performance, safety or sustainability. Our systems are specifically designed with that balance in mind by experts who understand your application. GoatThroat fluid friendly pumps are the safest, most reliable, and easiest way to accurately transfer any liquid. Custom configured pumps, fitting and accessories are fluid specific, meet compatibility requirements, and are designed as complete turnkey solutions to fit your exact transfer application. You don't have to choose between what is important for your business and what is good for your people. Here, there is no "no" there is only "not yet". Starting with ideas drawn from customer needs, we design and build useful equipment for safe liquid transfer for manufacturing, laboratories, agriculture, food and beverage, the energy sector and more. Our customers are very demanding, and we are grateful Only through their demands and their input can we grow. Deft and thoughtful, the team pares down each new design project to its essence to deliver the right product for the right price.Our Markets

Built of the highest quality materials right here in the USA, our equipment is rugged, efficient and configurable to meet each user's needs.- Agriculture

- Automotive

- Chemical Manufacturing

- Electronics

- Food & Beverage

- Furniture

- Manufacturing

- Golf, Lawn & Landscape

- Laboratory, R&D and Testing Labs

- Pharmaceutical & Medical

- Printing

- Universities

- Utilities

History

With an eye on the future importance of safety and sustainability in all walks of life, Westcott Distribution Inc. acquired Denel SOC Ltd.'s Pumpall Product Line in 2001 and rebranded it at GoatThroat Pumps. The talented team excels in developing, building and marketing chemical transfer equipment which improves worker safety and environmental compliance all over the world. We have developed testing processes to accurately evaluate which pump is suitable for what liquids. The chemical compatibility list is over 1700 tested liquids and counting.What We Make

- Pumps for Chemical and Food Applications

- Pumps for Flammable Liquids

- Pumps for Agriculture

- Pumps for TRI Reporting

- Pneumatic Systems

Agriculture Hand Pumps

Recommended and used by chemical companies including Bayer, BASF, Dow and others, there is no doubt. Users all agree that spill prevention beats clean up for most agricultural applications including:- Applying fertilizers, hormones, fungicides, wetting agents and pesticides to plants in greenhouses, fruit groves and fields.

- Decanting insecticide concentrates to smaller containers for mixing or dilution.

- Transferring fuel, lubricants & brake fluids to vehicles.