Did you ever think about the types of materials of construction? Chances are good that you haven’t because it is a lot easier to get another pump of the same kind that you know works. But a little work here will save a lot of wasted chemical… and throwing pumps in to the land fill … later.

If you want your transfer pump to have a long life, it is important to find out what materials of construction are suitable for use with the chemicals. And, just because a pump is expensive or has exotic materials in it, it still might not be the best. And when you get the information, ask them to verify that all of the parts of the pump are compatibly. Why? Sometimes, way up inside there might be one part which will cause the pump to fail… but not until after the warranty is over.

If you think about it, the companies making the chemicals want THEIR pumps to last, so they are an excellent resource for. you. And, your pump salesman should know his stuff enough to give you the information you need. There is no reason to WASTE chemical or resources any more.

To start: i. Ask chemical sales rep to ask factoryii. Consult pump manufacturersiii. Consult chemical guidesiv. Testing of pump materials of construction

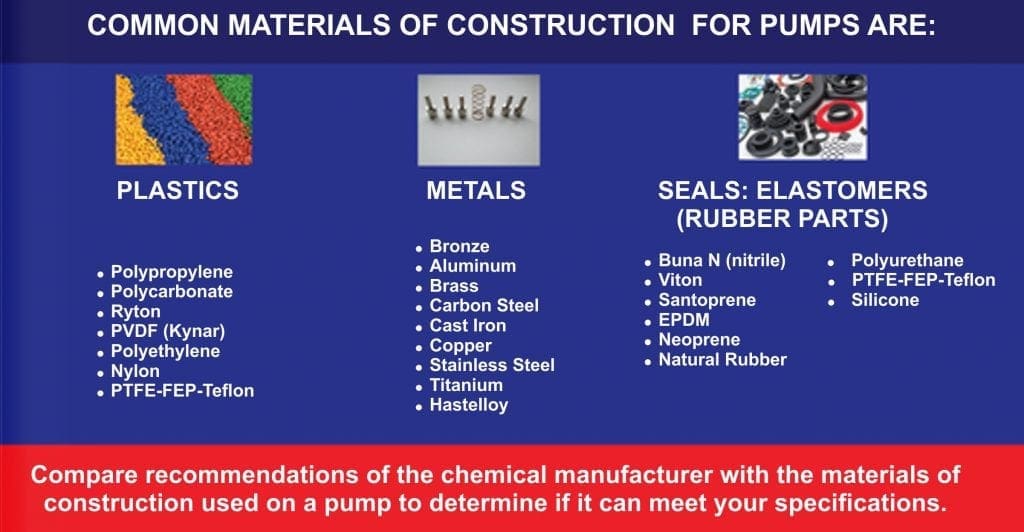

. Here are some of the materials.

PLASTICS

1. Polypropylene 2. Acetal 3. Polyurethane 4. Polyethylene 5. Ryton 6. Nylon 7. Kynar 8. PTFE-FEP-Teflon

METALS

1. Bronze 2. Aluminum 3. Brass 4. Carbon Steel 5. Stainless steel – 304 or 316 6. Cast Iron 7. Copper 8. Titanium 9. Hastelloy

ELASTOMERS (rubber components)

1. Buna N (nitrile) 2. Viton 3. Santoprene 4. EPDM 5. Kalrez 6. Neoprene 7. N atural rubber 8. Polyurethane 9. PTFE-FEP-Teflon

HOSES Work with your pump supplier to get the right hose which will be affected by the kind of pump it is.

Finally, compare recommendations with materials of construction with the pump you want to use – tell the supplier what you want and see if they can meet your specifications.