The Safe and Innovative Alternative Part 3 of 3

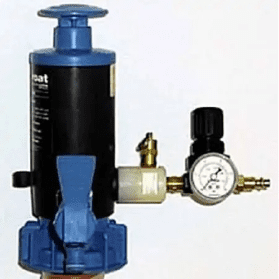

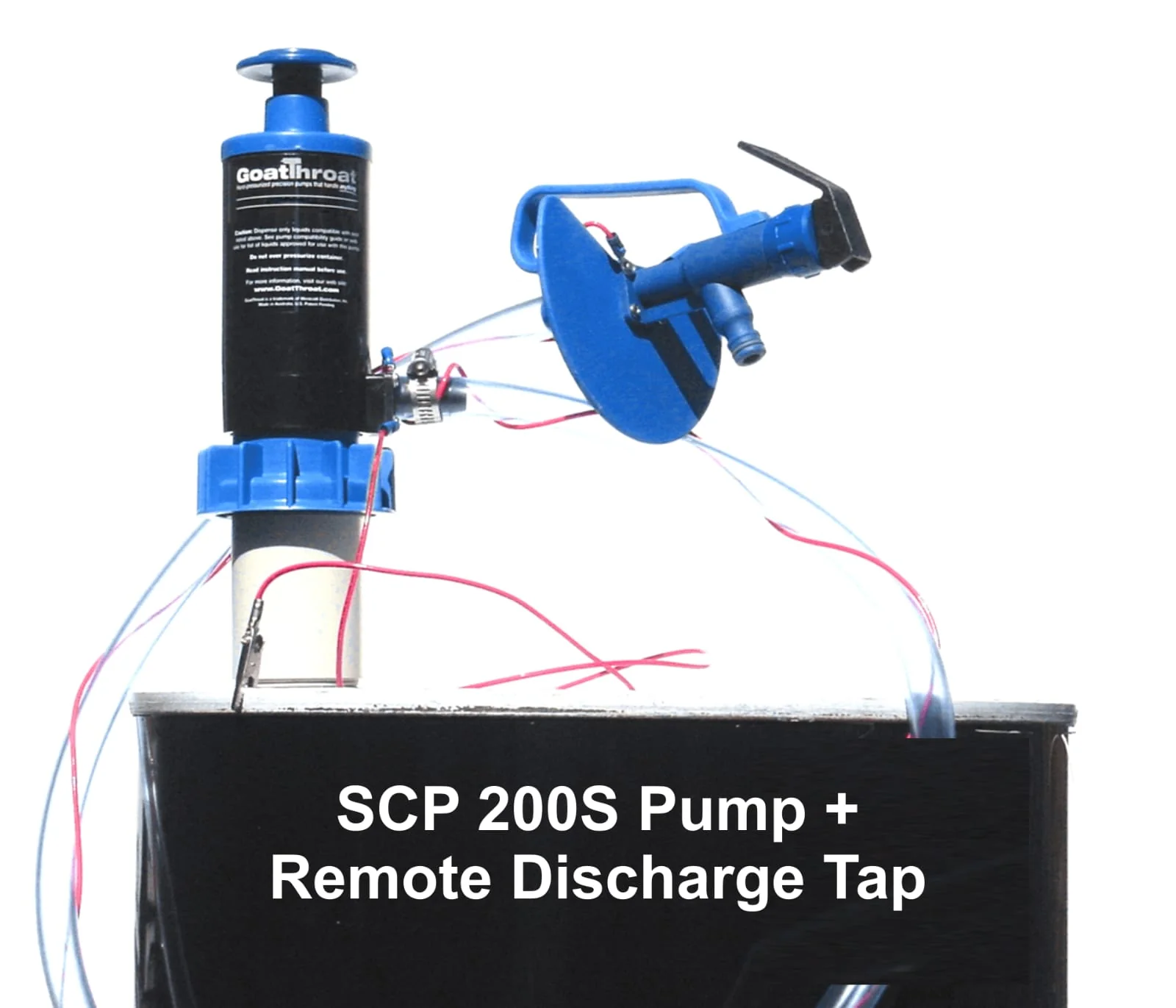

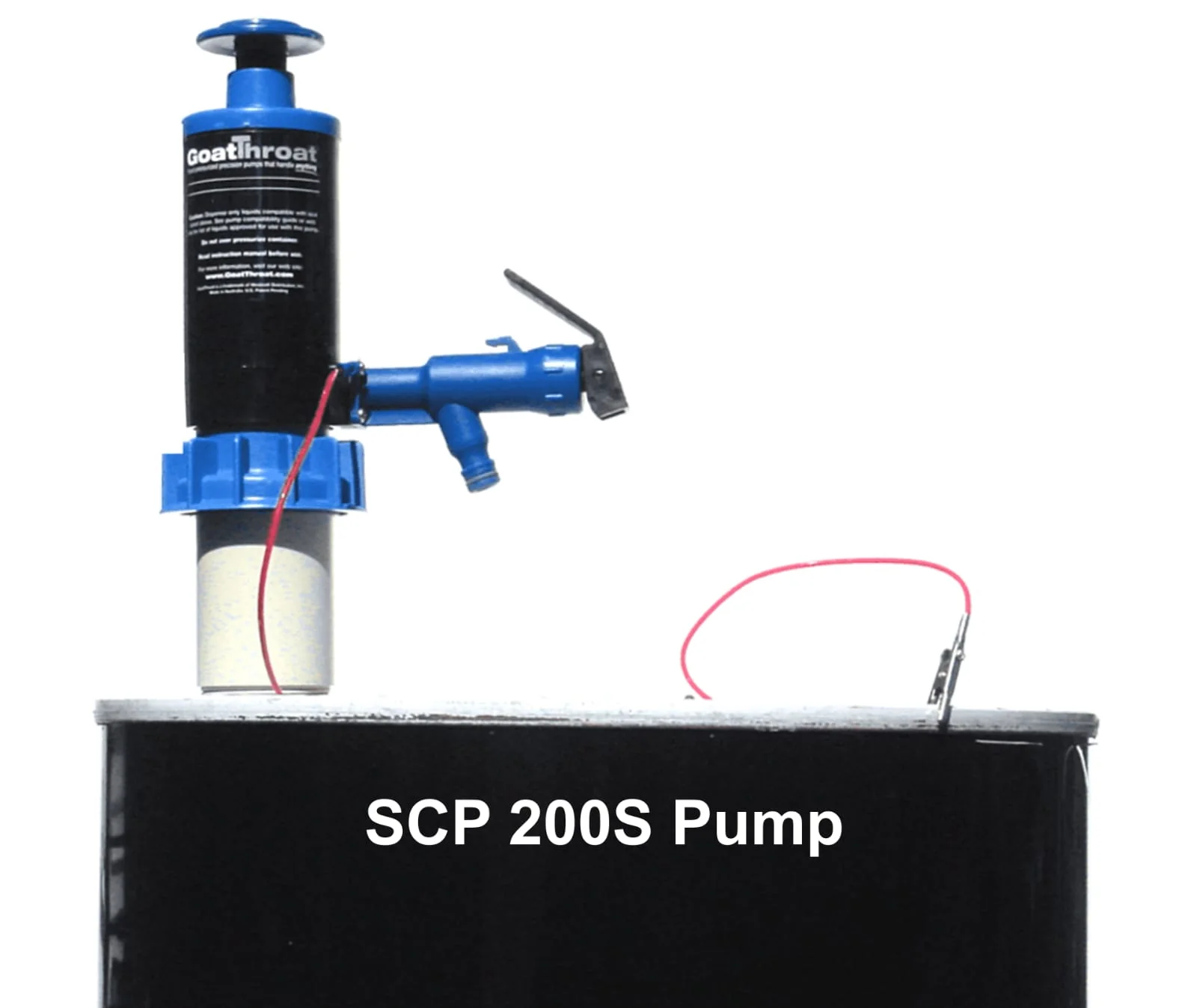

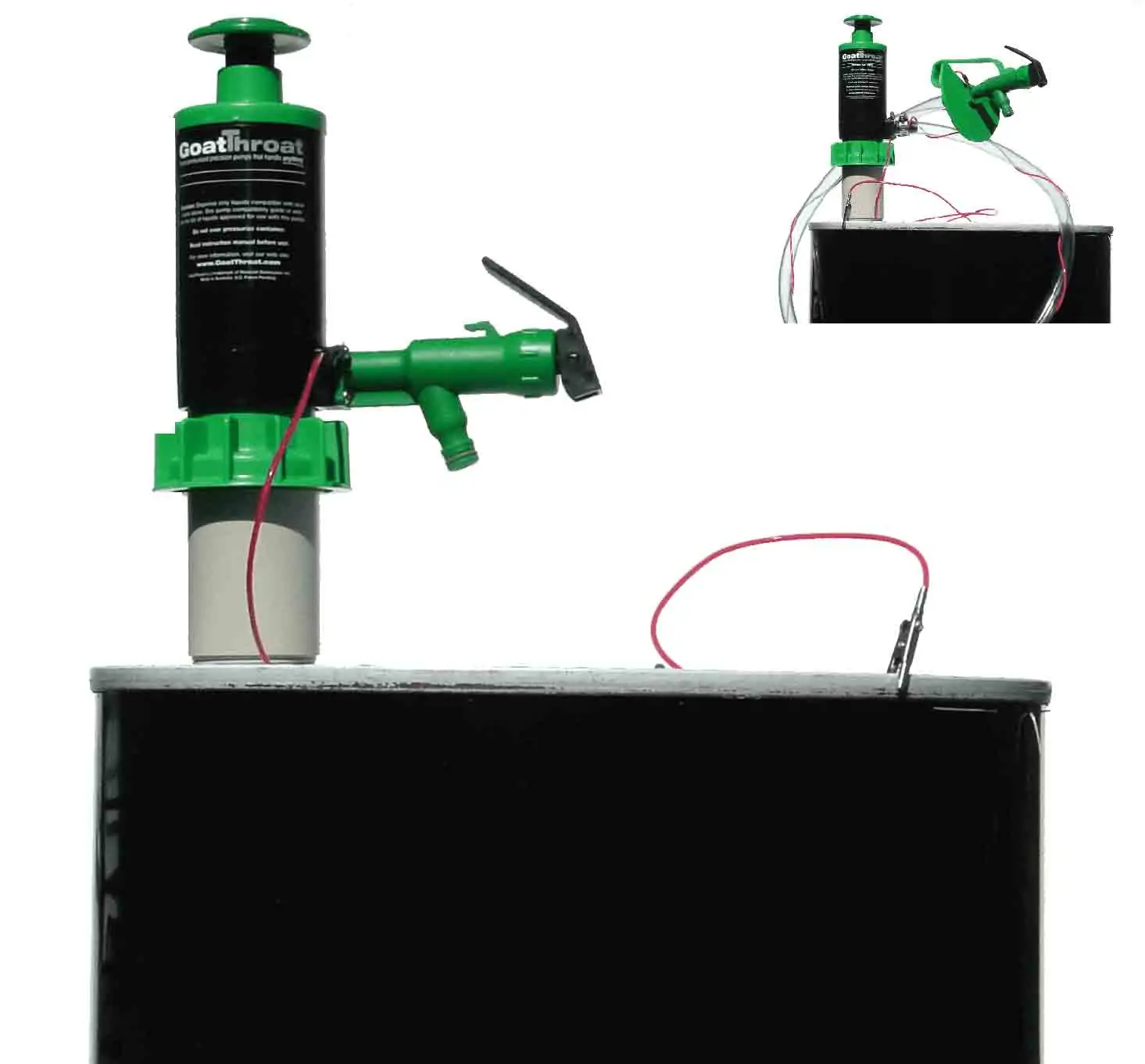

What is the antidote to unsafe chemical-handling processes at a plant, lab, or facility? Having a safe, dependable way to access and transfer liquids that doesn’t include tipping barrels and containers or relying on gravity for flow is an incredible first start. That’s why many businesses are upgrading to GoatThroat® pumps after auditing their practices for safety and spill reduction. GoatThroat pumps deliver a one-pump dispensing that is predictable and easily controlled with its spring actuated flow control. What’s more, these pumps have a sealed system which eliminates vapors that could create a dangerous indoor environment. Many states have closed-use requirements that make this a necessity. GoatThroat pumps are compatible with thousands of chemicals, and meet requirements set by the EPA, OSHA and other regulatory agencies. In addition, these pumps meet both NFPA 77 and NFPA 30 requirements regarding flammable liquids.

The simplicity of our pump designs also adds to the safety of these pumps. Many of today’s popular pumps feature electric components and movable parts that create a risk for sparks when flammable liquids are being used. Because we don’t have any electrical in our designs, these risks are eliminated, helping you to store containers of liquids more efficiently. In fact, many enterprises are able to save employees time by storing liquids near work areas for point of use liquid delivery.

Many people who work with GoatThroat pumps compare the way they operate to what you would expect from a beer pump. Each pump’s design allows for a smooth, highly controlled flow. The operator has full control over how much liquid is dispensed and the rate of speed. In addition, it is possible to leave the pump’s spigot open to create a continuous flow. The simple design is efficient for the worker and save time and money with no inventory loss.

Discover how upgrading to GoatThroat pumps can reduce common spill risks and actually save your business a lot of money over the lifespan of each pump by looking at our products directly, or reading through case studies in your industry. If you have any questions, fill out our contact form or give us a call +1.646.486.3636—we’ll be happy to assist you in finding the right dispensing solutions for your needs.