Automotive Industry Case Studies

FLEET OPERATIONS – REDUCING VOCs

Learn how the Aquarion Water Fleet manager saved money and improved efficiency by using a safer chemical transfer pump.

An important lynchpin to customer service and customer retention is a smooth operating service center. Most auto centers use a broad range of chemicals including degreasers, windshield fluids among others, and they are always searching for the best, most efficient ways to handle them. Inventory management is a critical component of the manager’s day to day operation. Questions that always arise are whether it is better to purchase smaller, more manageable quantities of the fluid at higher prices which can be poured directly out of a 1 gallon or a 5 gallon container or to purchase larger quantities and then have to deal with transferring the fluids out of the container safely. To top it off, OSHA and EPA have increased environmental health and safety (EHS) regulations so decision making in this area is critical.

A service manager at the Aquarion Water Company in Connecticut recently faced this dilemma.

To save money for his company, he began purchasing 30 gallon containers of a very evaporative degreaser together with the recommended dispensing pump. Jim found that the pump did not seal off the bung hole and much of the expected saving were evaporating into the air. Further, VOC’s such as hexane and methanol in the air are not healthy for workers, so the concern for the health and safety of the worker became very important. He looked for a pump which would eliminate the evaporation and give him the control in dispensing. Finally he purchased a GoatThroat™ pump with Viton seals and is very pleased with the results.

According to the manager, “We don’t have problems with evaporation any more. We can pump 1 or 2 strokes with the piston and then the drip proof faucet lets us dispense exactly how much degreasing fluid we need to fill our canisters. This is a great cost saver for my company because the volume buying is working and now we are delivering the fluids safely for the guys in the shop.”

INTEGRITY AUTO SPECIALISTS

Car refurbishing company deploys GoatThroat Pumps for safe handling of acetone.

In just over a decade, Integrity Auto Specialists has grown into a dynamic leader in the auto reconditioning business with over 25 fleet operations from the Atlantic Ocean to the Rocky Mountains. When a car dealership receives truck load of cars which have traveled hundreds – or thousands of miles on the flat bed, many times there are small chips in the paint and chrome from rocks and debris. Integrity Auto Specialists craftsmen fix these so the customer gets a perfect car.

At the Chesapeake, Virginia Headquarters, technicians fill 1 gallon container of proprietary mixed thinners for distribution to the craftsmen at the centers throughout the US. Using a pull action pump with leather seal,, the technicians were regularly sprayed with the fluid when the pump seals failed.. In 2002, in an effort to create a more responsible corporate environmental strategy, and to improve worker safety, Integrity Auto switched to GoatThroatTM Pumps for this filling station. Early in 2003, after several months of use without any problems or failures, management bought a GoatThroatTM pump for each of its service centers throughout the US for dispensing acetone.

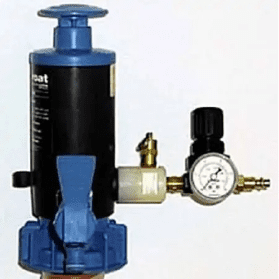

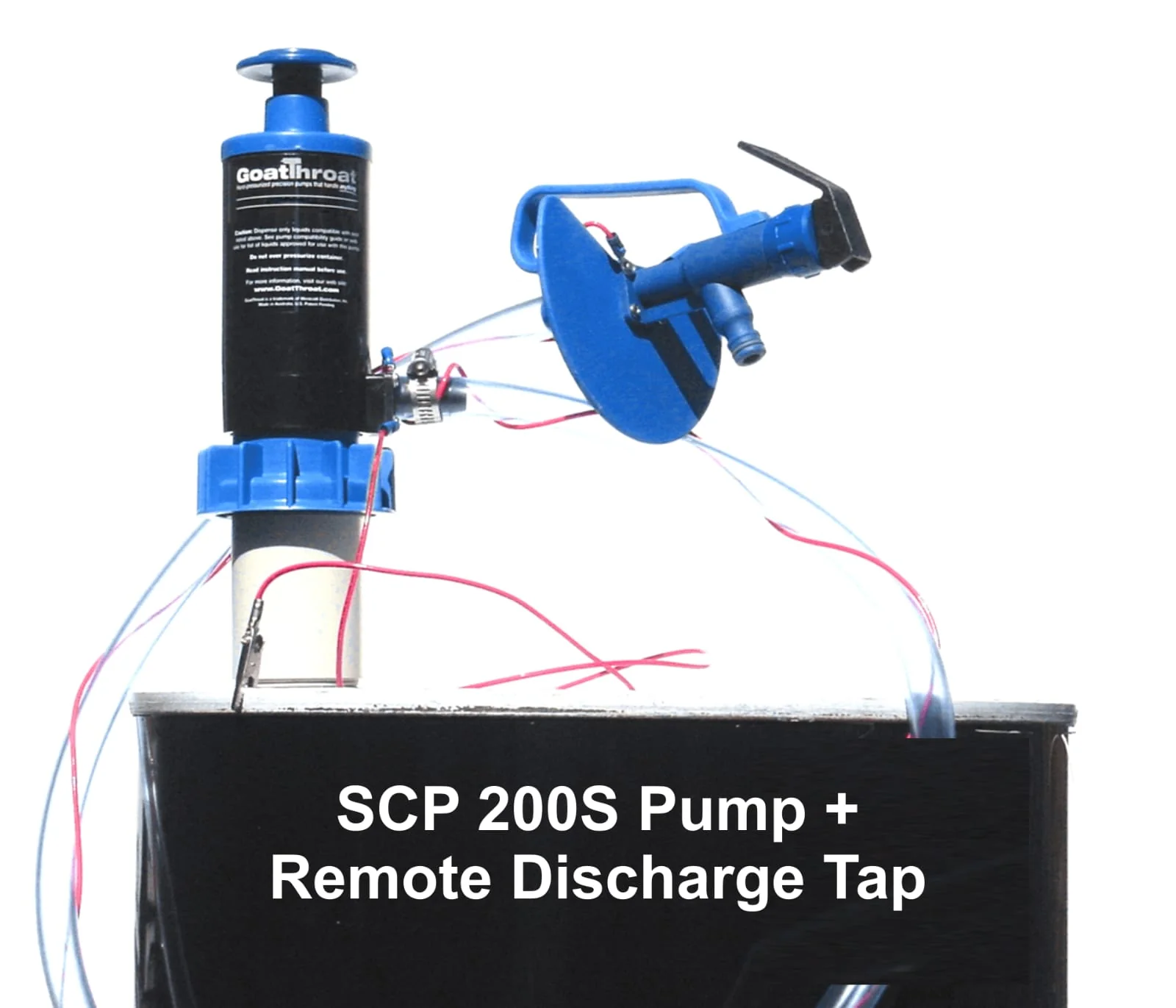

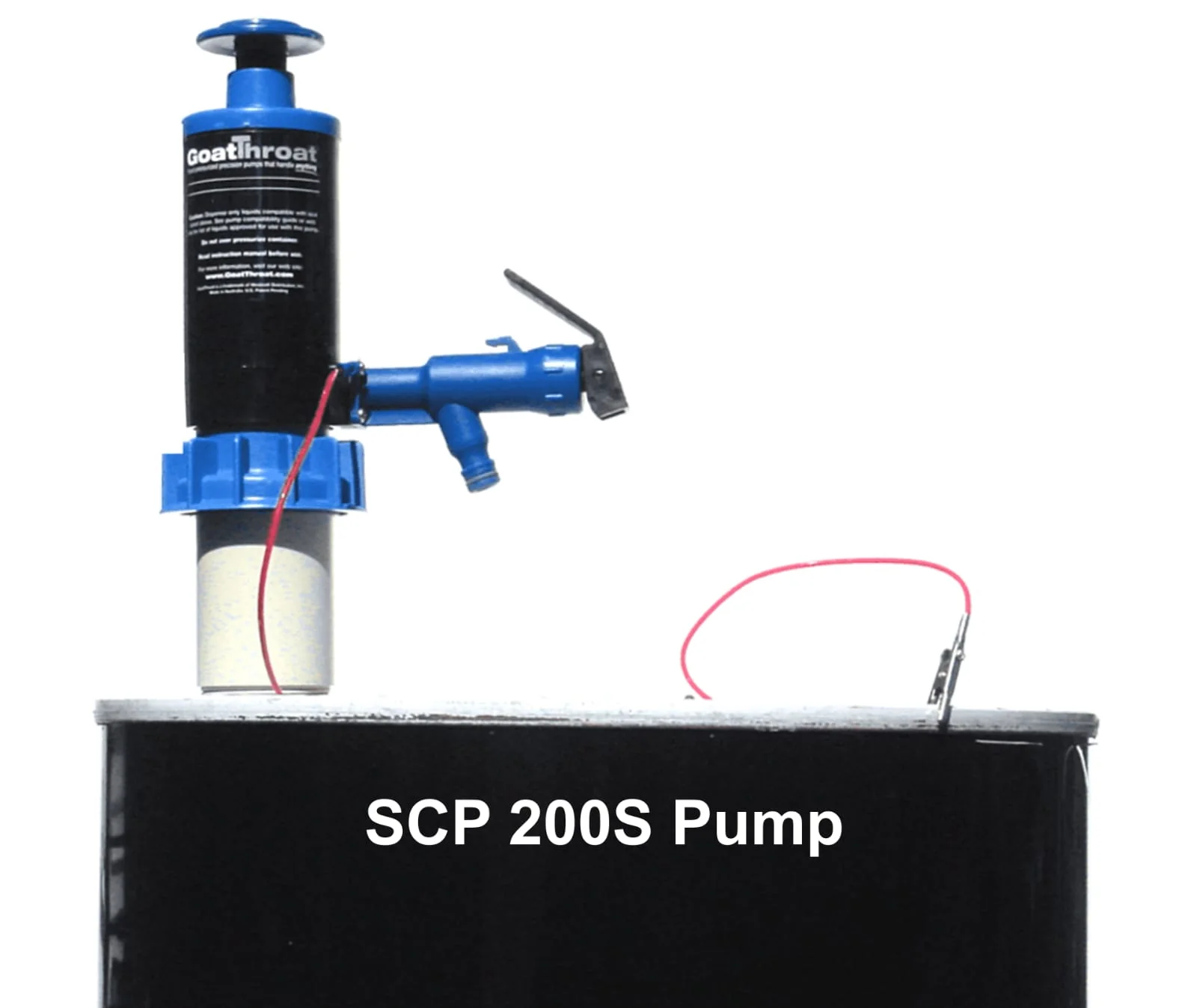

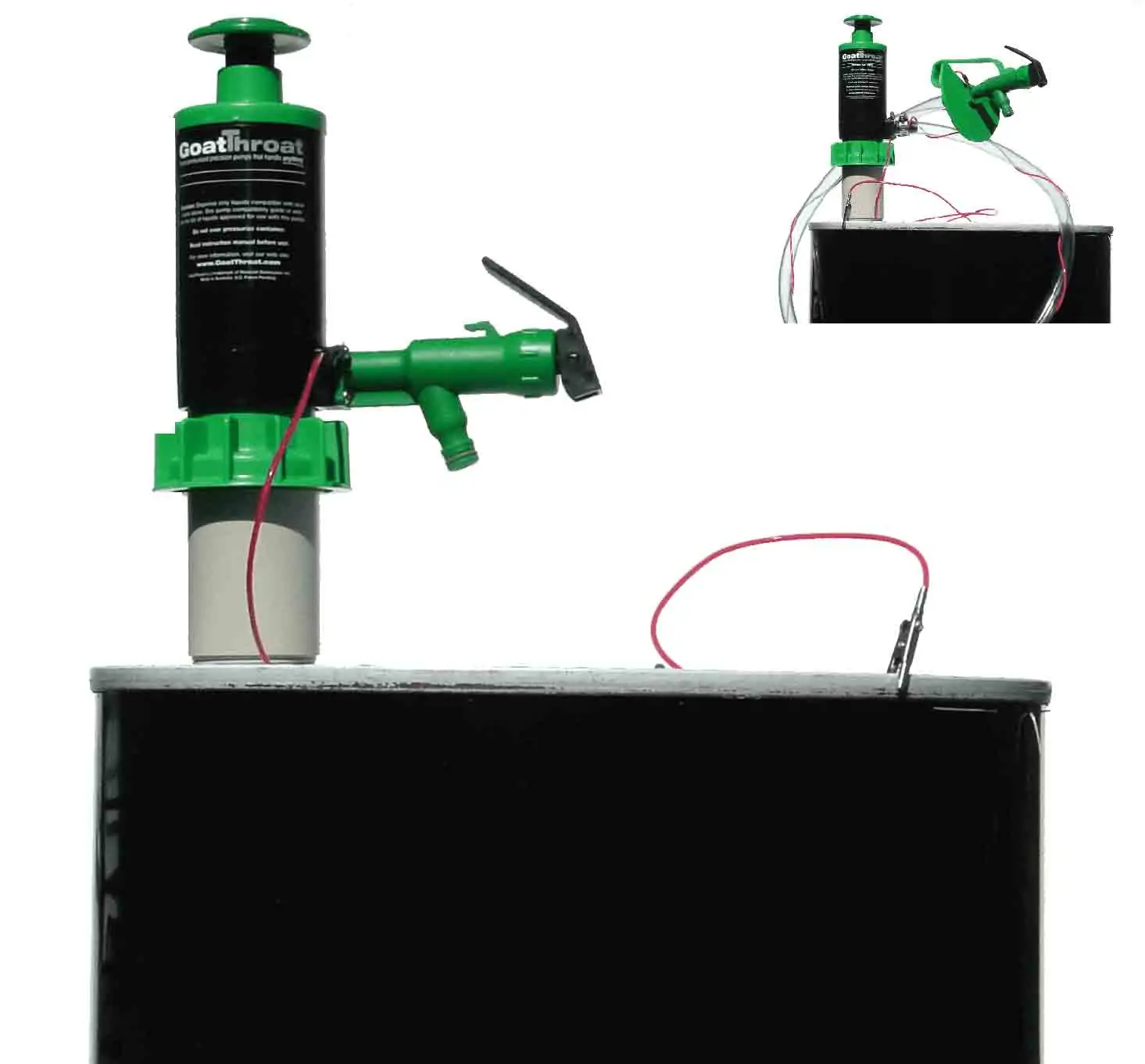

Kept in a safety cabinet because it is a regulated flammable, acetone is used regularly throughout the day. The 55 gallon drum must have bonding and grounding wires attached prior to dispensing the acetone. John George, manager of the Western Region, points out that his people are still using the GoatThroatTM after 3 years. “The previous pump which we used lasted only a few months before it began to fail. We had to throw it away because it was too much trouble to replace the leather seal. We have been using our GoatThroatTM as a hand pump for over 3 years. We have had to replace the tap o-ring a couple of times, but the whole replacement takes less that 5 minutes, and then we are ready to go again. Recently, we added the BillyGoat Shop Air adapter which eliminates pumping the container by hand, and are very pleased with it. The shop air adapter is set at 2psi which is a very low pressure, and our fluids are always ready for use when ever we need them . We simply open up the tap and dispense a quart or a gallon depending on our need. These pumps have eliminated VOCs from the acetone drum except when we are dispensing it. This tool has improved the safety of our workers and helped us to be more compliant with local regulations. And we don’t spend time cleaning up spills any more.”

AT THE CAR WASH

Major car wash chain discovered GoatThroat pumps and stopped pouring money down the drain.

After twelve years of pumps breaking down, wasted materials, and messy clean-ups, Matt Delange, General Manager of the WashWorks® car wash finally found the solution he’d been looking for: GoatThroat pumps. “They worked and worked perfectly right from the start,” said Mr. Delange, “No more money down the drain.”

WashWorks car wash, whose slogan promotes them as “Not just a car wash,

a car care experience,” has been a mainstay in Baltimore for fifteen years. This environmentally friendly company was founded by Mr. Delange’s father and has a following of loyal customers and a reputation for excellence. Everything about the operation is professional and buttoned-up, which is why Mr. Delange was so delighted to find GoatThroat pumps.

“Before GoatThroat, we’d use any drum pump that was on the market and could pump the product, knowing that it would break down in no time at all,” noted Mr. Delange. “It was frustrating to me and my employees. Every two to three months I’d have to purchase a new pump. I can’t tell you how many we went through. Then I found GoatThroat. These pumps work and they never break down.”

Mr. Delange has been using the same durable GoatThroat Pumps for three years to transfer vinegar for window washing and Stoddard for tire and white-wall cleaning. At first, he was shocked at the price of the pumps – at over $140.00 each, they were more expensive than any other he’d previously purchased. But when he saw how well they performed and how durable they were, he realized they were well worth the money. “After we had our pumps for one year, I purchased two more for back up,” said Mr. Delange, “and this time I knew I was getting a bargain. They’ve been sitting on the shelf and I haven’t had to use them. I know the original one won’t break.”

None of the previous pumps used by WashWorks compared to GoatThroat. Utilizing them on a daily basis, Mr. Delange soon came to appreciate what a great tool they were. Each pump can drain a drum dry, so an inventory loss was no longer a problem. The pumps are leak proof, which makes transferring products safer. Plus, it eliminates spills and the need for clean up. WashWorks employees approved of the pumps, too. With just one touch needed to fill up a spray bottle, there’s no time wasted and no mess to deal with.

GoatThroat pumps are designed to fit any container from 2-gallon jugs to 55-gallon drums and can pump virtually any liquid. WashWorks uses the GoatThroat GT 100 with a nitrile seal to pump vinegar from 30-gallon drums and the GT 200 with EDPM seal to transfer Stoddard from 55-gallon drums.

Since he began working with GoatThroat pumps, the only maintenance Mr. Delange has needed was to replace the “O” ring, which wore out. “When the “O” ring failed, I called Nancy Wescott, President of GoatThroat, and told her I wanted a new pump. She refused to sell me one because she knew the pump I had was fine. It wasn’t broken, just needed a new seal. She took care of it right away. Now, that’s great customer service.”

GoatThroat pumps have been perfect for WashWorks. Instead of worrying about equipment breaking down, it’s allowed the company to focus on what they do best: taking care of their customers while ensuring that things run smoothly.