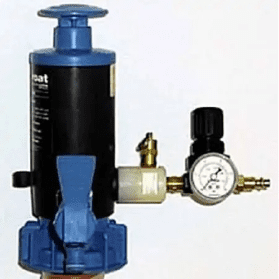

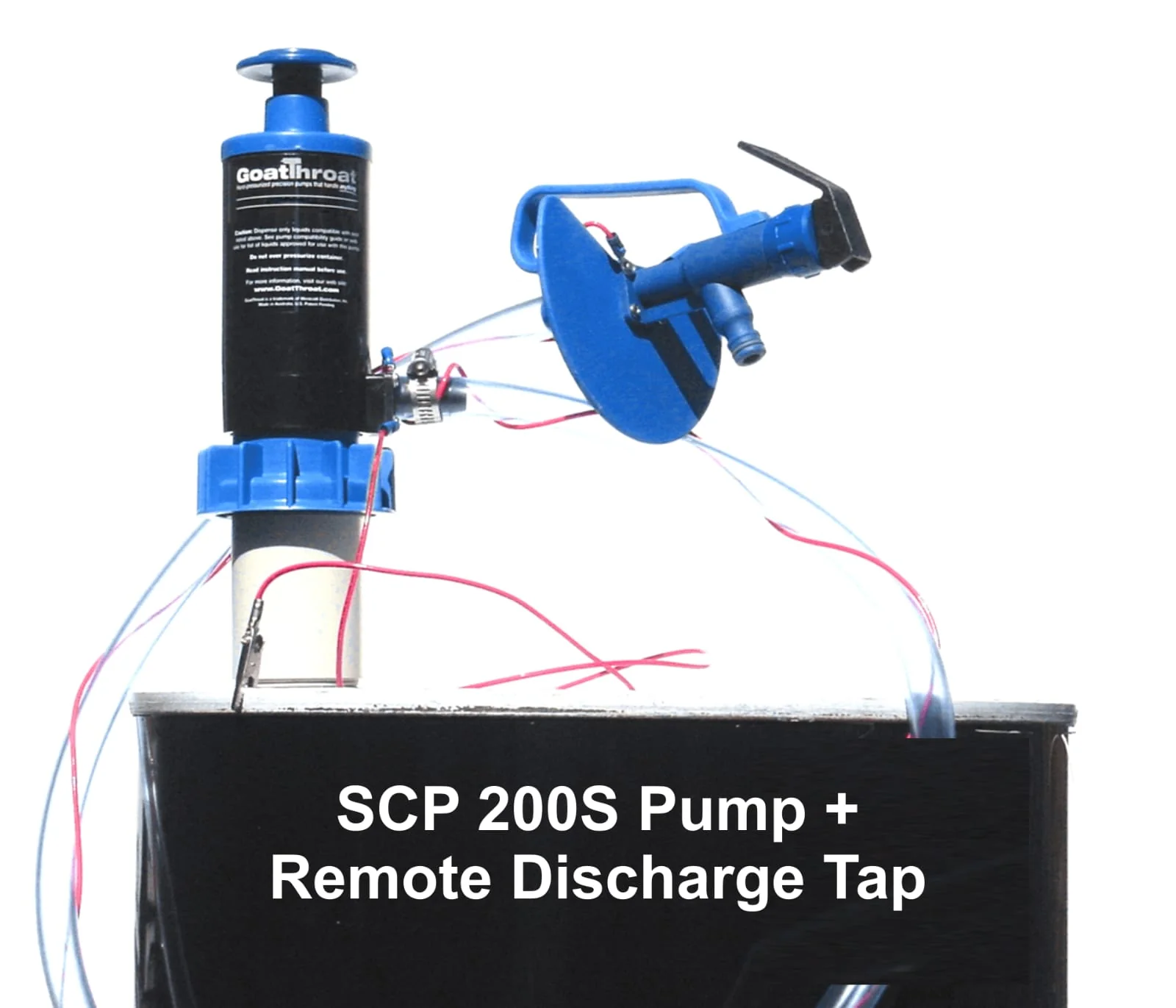

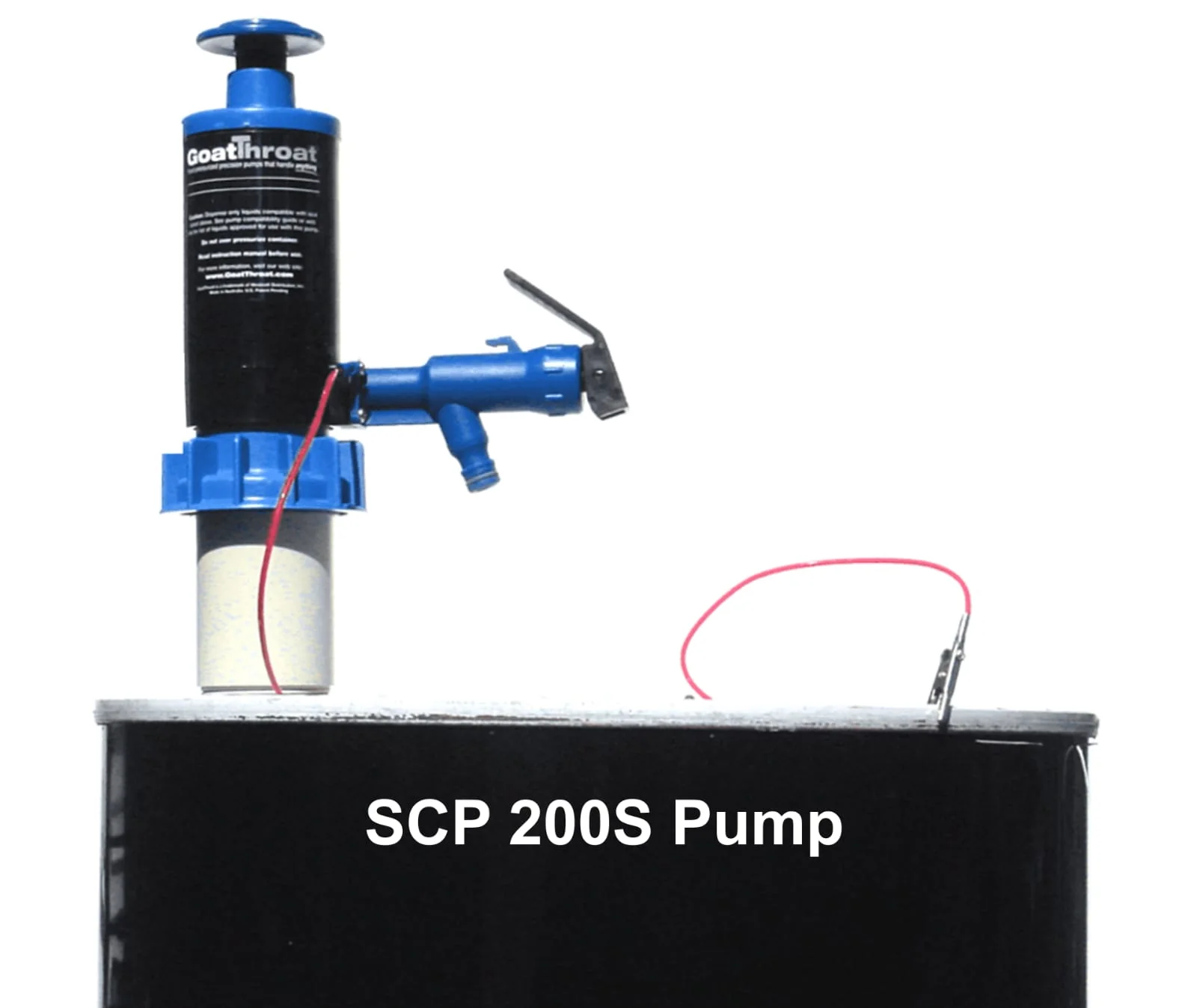

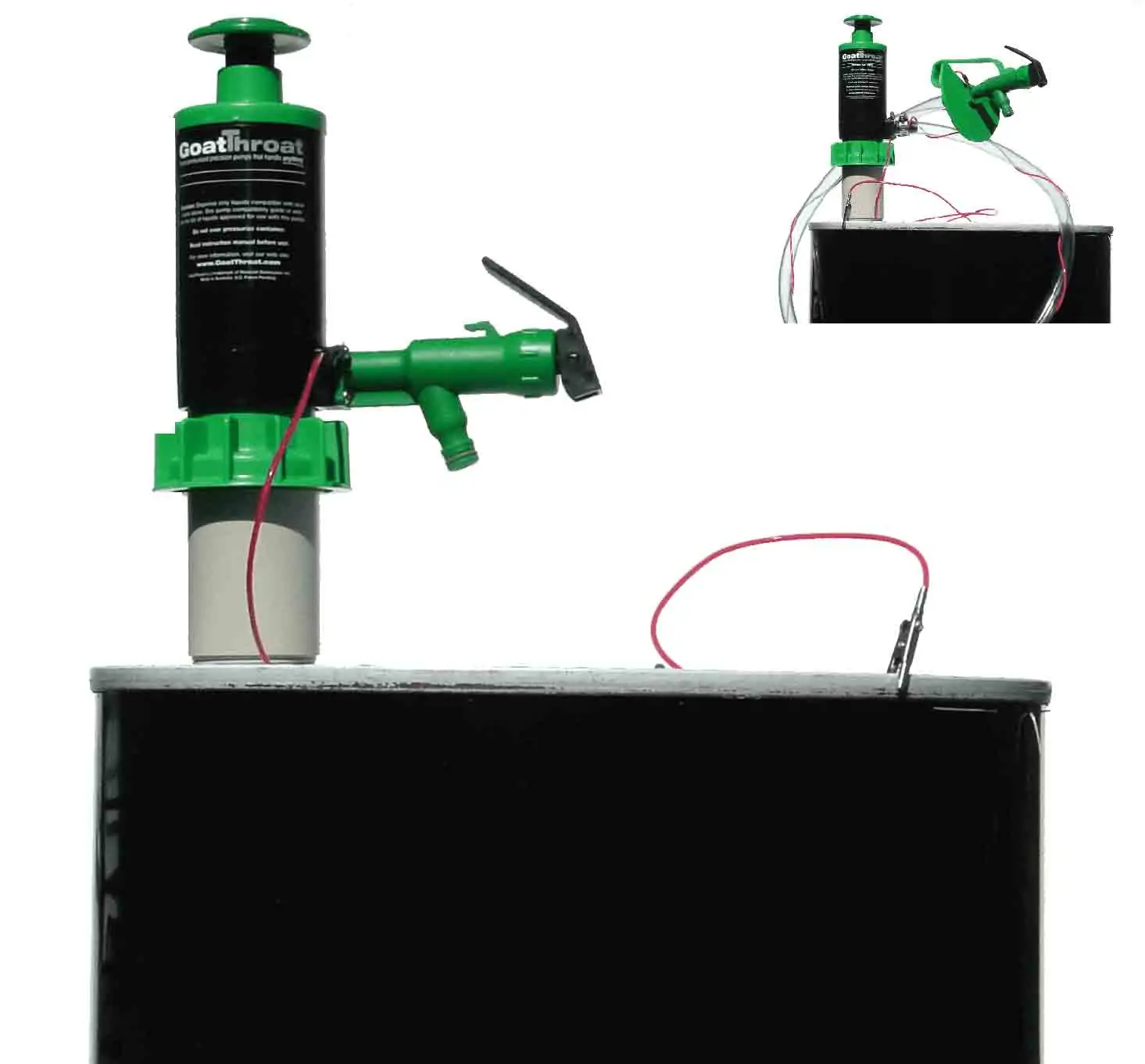

Golf course management involves the purchase, storage, and dispensing of many types of liquids from fertilizers to insecticides and having to deal with all of the issues that come from these activities. Accordingly, Mike Higuera, Jr., Manager of The Ranch Golf Course in San Jose, CA suffered such difficulties when using high volumes of liquids: spills, employee injuries, leaks, and loss of product. The initial issue was that the 55-gallon drums of liquids were stored horizontally in a dedicated chemical shed with spigots mounted on the fronts. Positioning the full drums was both difficult and dangerous. Then, because they projected into the room, the spigots were often subject to accidental contact, sometimes being completely dislodged. The resultant mess was expensive and, depending on the chemical, dangerous to employees. “I had tried a suction pump with an upright 55 gallon drum,” said Higuera. “But it had a three-foot stroke and was hard to pump. My guys were constantly straining muscles using it. I read the trade press to keep up on any new technologies that might make my job easier,” he said. “That’s where I read an article about Goat Throat pumps. I had tapped a few kegs in my youth, so I was familiar with the technology that permitted the drums to be positioned vertically and then easily pressurized with short strokes. I added it to the budget and bought my first one. That was six years ago and not only have the pumps turned out great, I’ve also added some options that make life at the course even easier. One is a remote tap that comes at the end of flexible tubing so we can set the receptacle on the floor to fill it. That is very helpful when we’re pumping one of our fertilizers, liquid iron. It weights 10 pounds per gallon, so if the employee is filling a 5-gallon can, he would end up holding 50 pounds. The other option was to use an adaptor with an air regulator on top. We hook the pump up directly to our compressor, so we don’t have to hand pump. “The bottom line is that the pumps have saved us time, injuries, and product. They paid for themselves very quickly.”

GoatThroat Pumps

Safety by Design. Engineered for Life.

Not sure? Start Here.

Configure Your System

Not sure? Start Here.

Configure Your System

Not sure? Start Here.

Configure Your System

- Nitrile Pump & Tap Line

- Pump

- Groundable Pump

- Groundable Pump with Tap

- Repair & Replacement Parts

- See All Nitrile

Nitrile (Buna) elastomeric gaskets throughout the fluid path and other internal parts.

- Viton Pump & Tap Line

- Pump

- Groundable Pump

- Groundable Pump with Tap

- Repair & Replacement Parts

- See All Viton

Food-grade Viton elastomeric gaskets throughout the fluid path and other internal parts.

- EPDM Pump & Tap Line

- Pump

- Groundable Pump

- Groundable Pump with Tap

- Repair & Replacement Parts

- See All EPDM

EPDM elastomeric gaskets throughout the fluid path and other internal parts.

- Santoprene Pump & Tap Line

- Pump

- Groundable Pump

- Groundable Pump and Tap

- Repair & Replacement Parts

- See All Santoprene

Food-grade Santoprene, EPDM and Teflon elastomeric gaskets throughout the fluid path and other internal parts.

Not sure? Start Here.

Configure Your System

- Agriculture Hand Pumps

- Automotive Hand Pumps

- Electronic Manufacturing Pumps

- Furniture Industry Chemical Pumps

- Food Grade Pumps

- Golf Course and Landscape Pumps

- Government

- Laboratory, R&D Testing Pumps

- Industrial Manufacturing Drum Pumps

- Pharmaceutical & Medical Drum Pumps

- Printing

- Retail

- University Lab Drum Pumps

- Utilities

Not sure? Start Here.

Configure Your System

Not sure? Start Here.

Configure Your System

Not sure? Start Here.

Configure Your System