Wash Works finds GoatThroat Pumps

…………….and stops pouring money down the drain

After twelve years of regular hand pump replacement, wasted materials, and messy clean-ups, Matt de Lange, General Manager of the Wash Works Car Wash finally found the pump he’d been looking for: GoatThroat. “They worked and worked perfectly right from the start. No more money down the drain.”

Wash Works Car Wash, whose slogan promotes them as “Not just a car wash, a car care experience,” has been a mainstay in Baltimore for fifteen years. This family friendly company was founded by Mr. de Lange’s father and has a following of loyal customers and a reputation for excellence. Everything about the operation is professional and buttoned-up, which is why Mr. de Lange was so delighted to find GoatThroat pumps.

“Before GoatThroat, we tried every pump on the market that could move the product. Most would break down in no time at all,” noted Mr. de Lange. “It was frustrating to me and my employees. Every two to three months I’d have to purchase a new pump. I can’t tell you how many we went through. Then I found GoatThroat. These pumps work and they have never broken down.”

Mr. de Lange has been using the same durable GoatThroat pumps for three years to transfer vinegar for window washing and petroleum solvent for general cleaning. At first, he was shocked at the price of the pumps – at over $140.00 each, they were more expensive than any other he’d previously purchased. But when he saw how well they performed and how durable they were, he realized they were well worth the money. “After we had our pumps for one year, I purchased more for spares,” said Mr. de Lange. “I haven’t had to use these spares yet.”

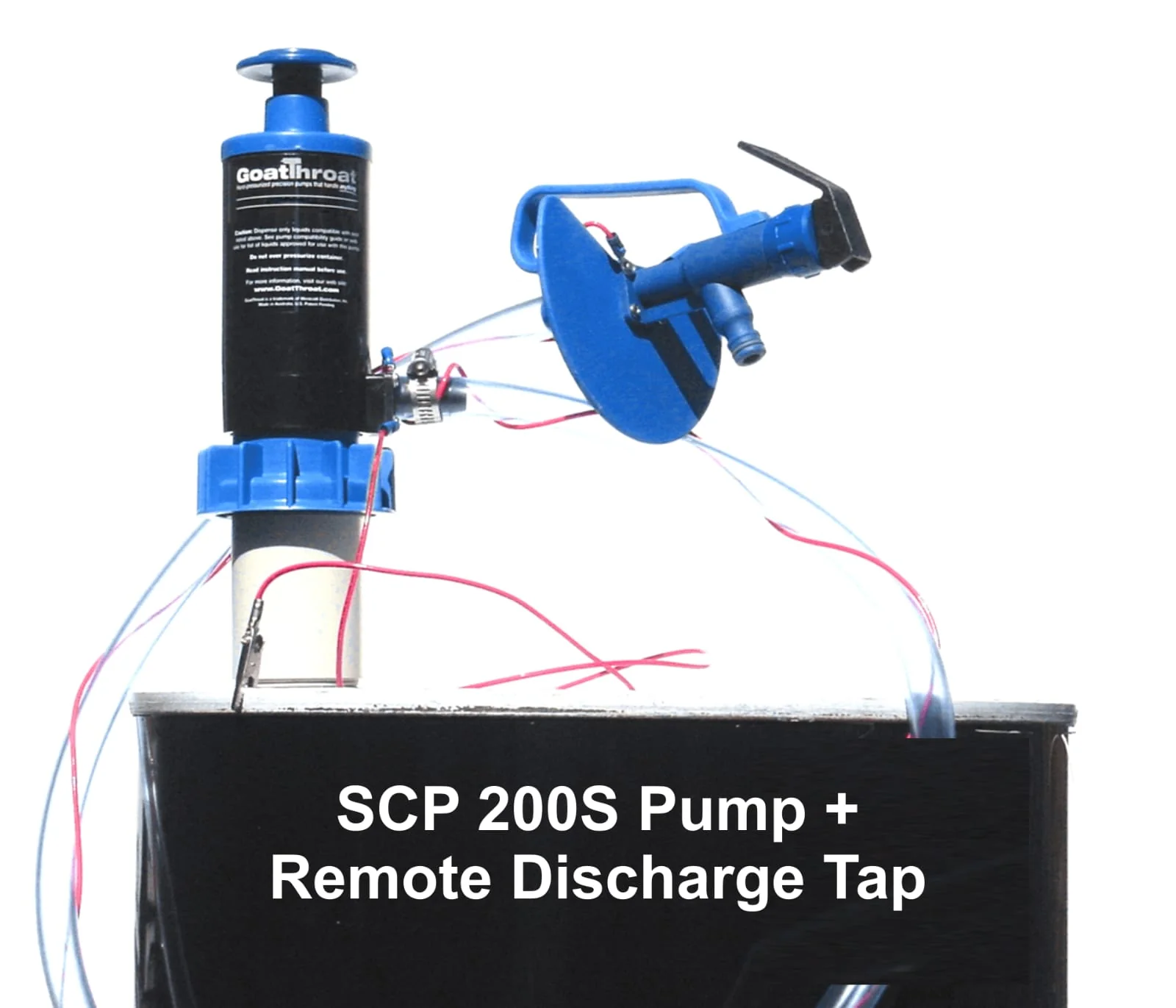

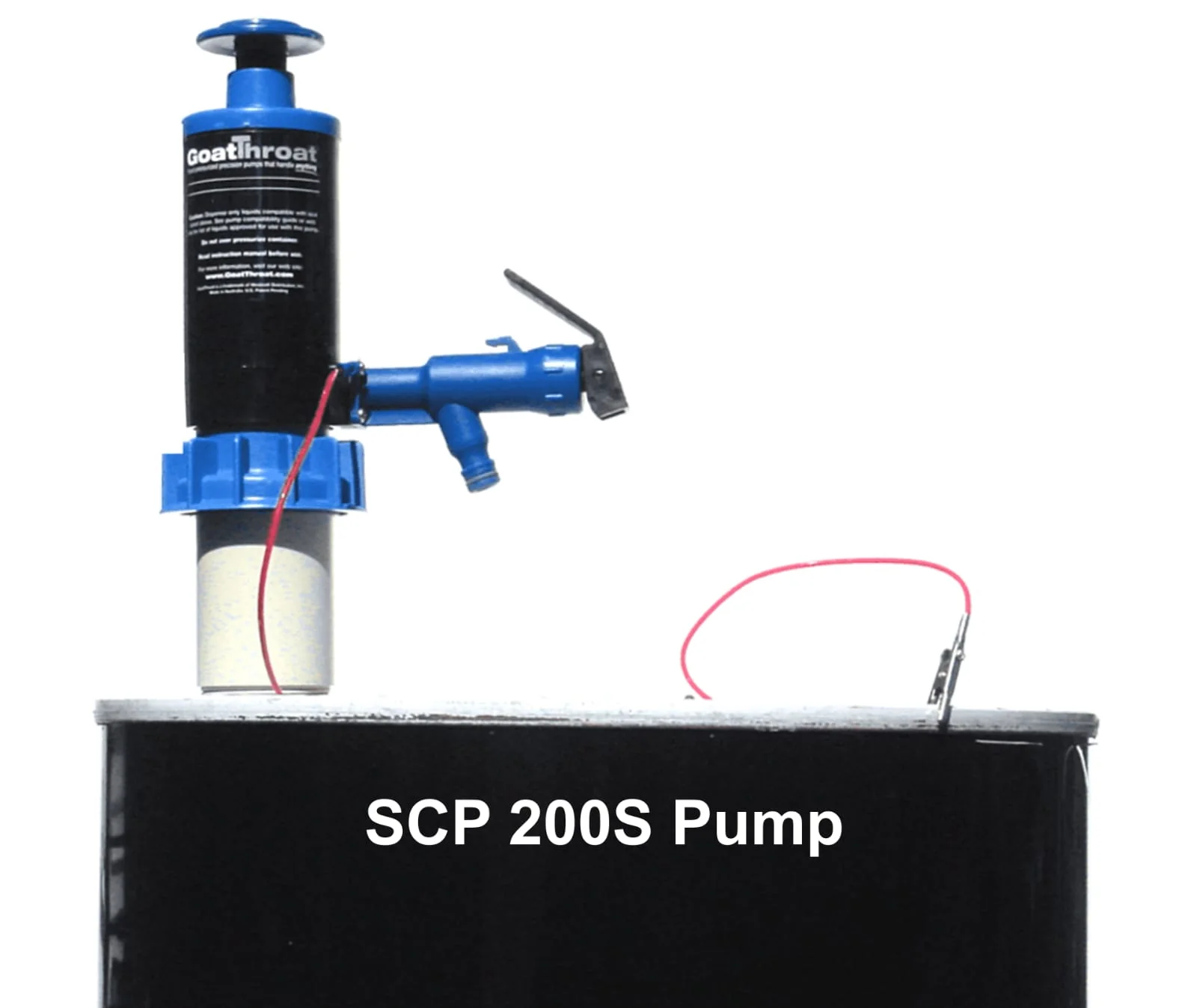

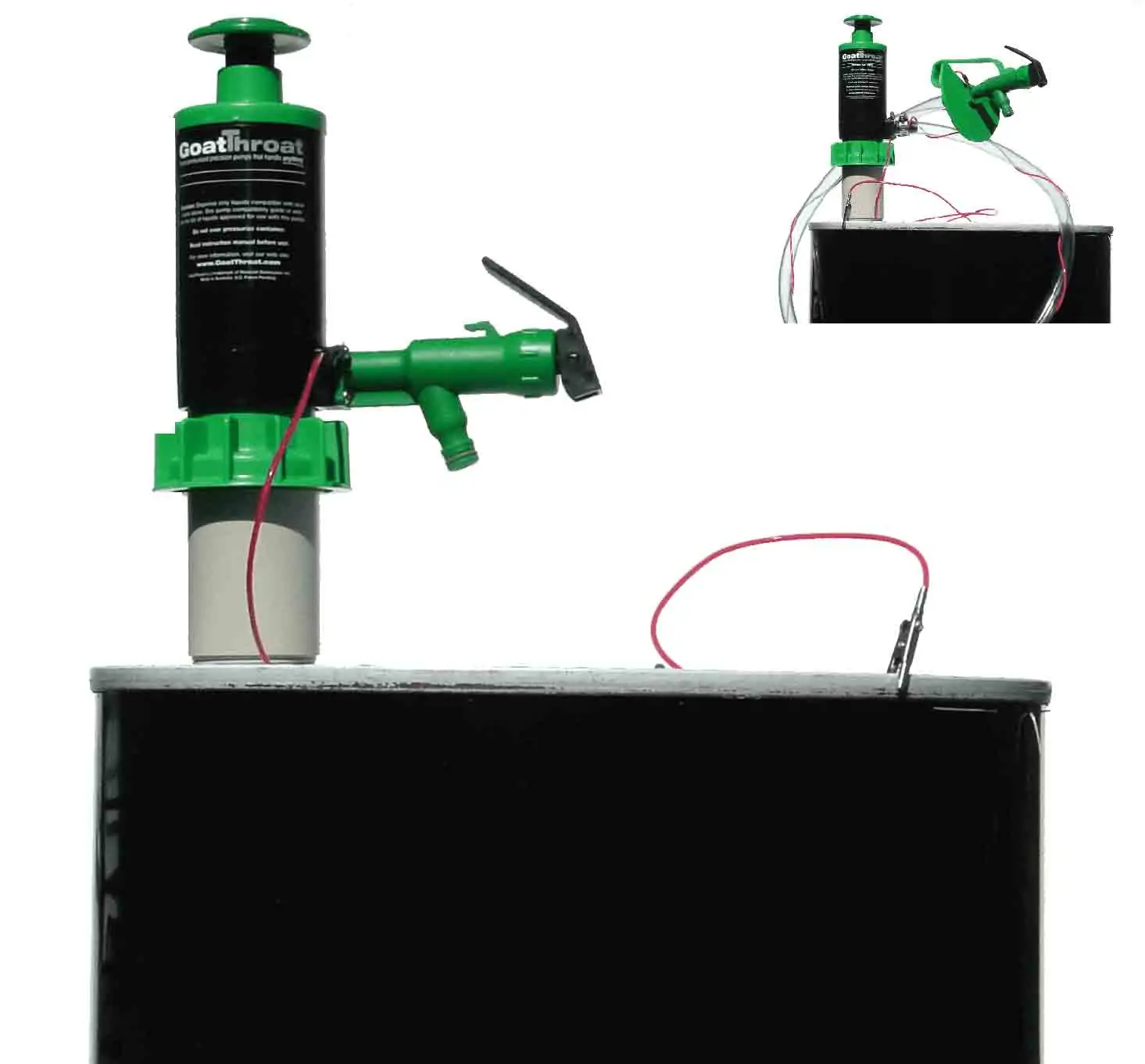

Utilizing them on a daily basis, Mr. de Lange soon came to appreciate the reliability of GoatThroat pumps. Each pump will drain a drum dry, so inventory loss is no longer a problem. The pumps are leak proof, which makes transferring products safer. Plus, they eliminate spills and the need for clean up, a major problem with earlier pump purchases. Wash Works line employees like the pumps, too. The pumps operate easily and deliver products instantaneously. There’s no time wasted and no mess to deal with.

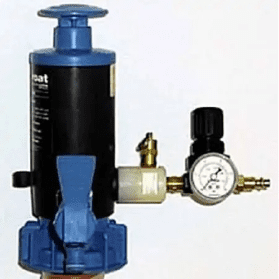

GoatThroat pumps are designed to fit any container from 2-gallon jugs to 55-gallon drums and can pump virtually any liquid. Wash Works uses the GoatThroat GT 100 with a nitrile seal to pump vinegar from 30-gallon drums and the GT 200 with EDPM seal to transfer solvents from 55-gallon drums.

Since he began working with GoatThroat pumps, the only maintenance Mr. de Lange has needed was to replace the “O” ring, which wore out. “When the “O” ring failed, I called Nancy Wescott, President of GoatThroat, and told her I wanted a new pump after two years. She refused to sell me one because she knew the pump I had was fine. It wasn’t broken, just needed a new “O” ring. She took care of it right away. Now, that’s great customer service.” GoatThroat pumps have been perfect for Wash Works. Instead of worrying about equipment breaking down, it’s allowed the company to focus on what they do best: taking care of their customers while ensuring that things run smoothly.