The majority of chemical spill problems occur while getting the chemicals out of the drums. Many small- to moderate-sized companies rely on workers to manually lift and tip the containers and pour the chemical into a smaller drum, so spills are inevitable, and spill kits and related equipment are necessary.

While there’s no substitute for planned maintenance programs that seek out, identify, and mitigate causes of spills and contamination, one thing is for sure: manual drum-emptying practices frequently generate spills that present management with OSHA-related work safety issues or problems with EPA regulations.

Plant management is never happy with the loss of costly, usable chemicals, particularly when a low-cost, preventive approach exists.

Handling Drums of Acetone at Carolina Castings

Located in High Point, NC, Carolina Casting, Inc. is a leader in polyester resin-based products for the furniture industry. For its customers, Carolina Castings creates bunn feet, finials, moldings and roto-casted table bases to include items such as chair backs, ornate fixtures, tabletops, mirror frames, highly complex assembled table bases and pedestals, and more. The process Carolina Castings employs can supply texture and color for the striking results their customers require.

The Problem: A large volume of acetone has to be dispensed daily. Large faucet-equipped drums of the chemical were stored upright in the chemical storage room. But for use, the 350 lb drums had to be moved to another location, placed on a cradle in a prone position, have bonding and grounding wires attached, and be tilted to permit dispensing through hand control of the faucet.

After dispensing, the bonding and grounding wires were disconnected and the container returned to the storage area and again placed in an upright position. According to plant engineer Dan Stiles, the process was slow, labor intensive, and subject to potential spills when transferring the flammable solvent.

“We use acetone as a solvent to clean hand tools, small containers, and machine flushing operations,” noted Stiles. “However, our primary use is to clean our finished product so that it is free of chemical component, flashing, and foreign debris. The finished product is then ready for painting or staining with a similar texture and acceptance of the final finish just as if it were its wood counterpart.”

The Search: Dissatisfied, Stiles tried using a rotary hand crank pump on the container, but found this unsatisfactory because the liquid would pulse at the spout and splash on the employees during dispensing. Additionally, these pumps were unreliable after a few months, requiring costly repairs. Stiles then investigated air-driven pumps, but this was unsuitable because of high initial costs, expensive replacement parts, and high maintenance costs.

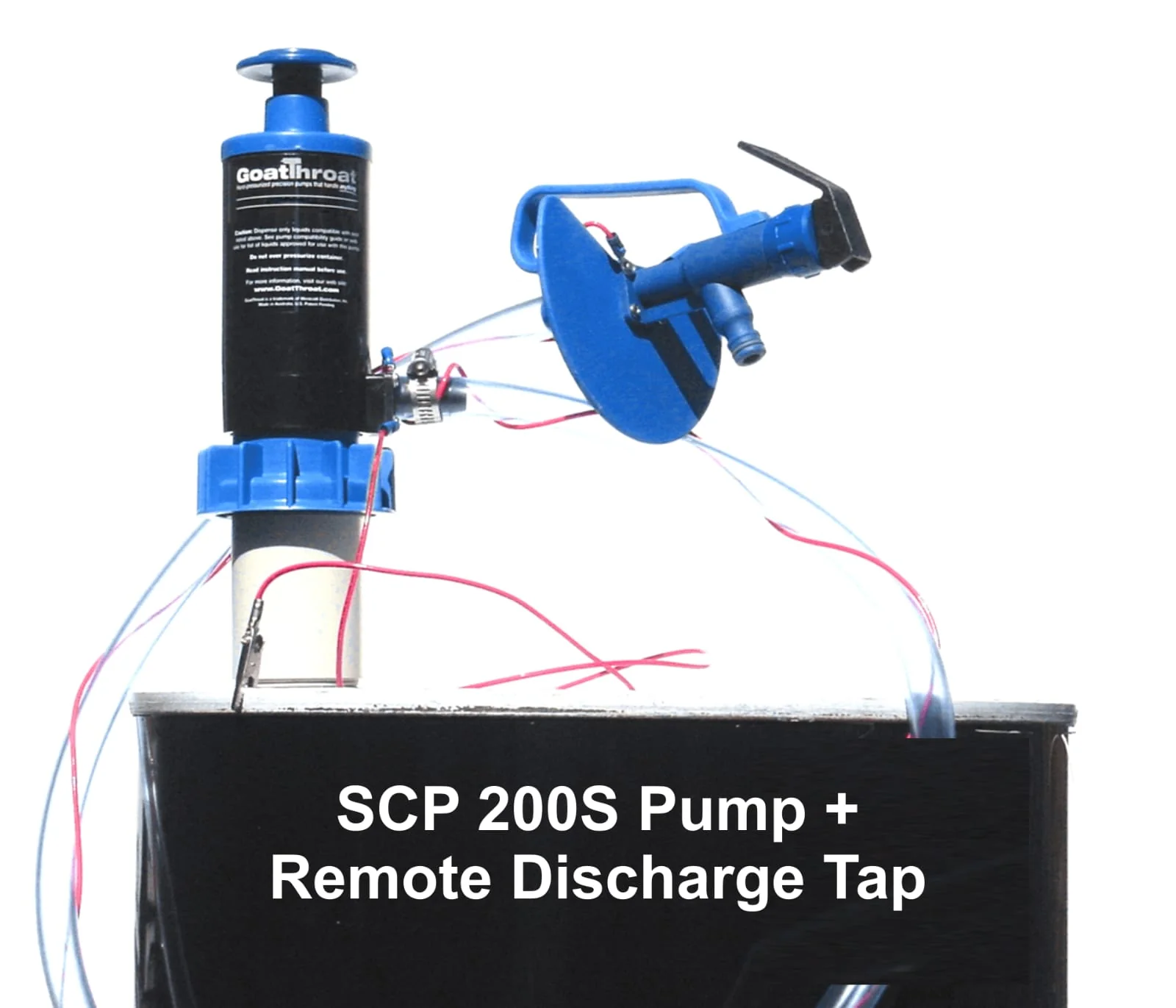

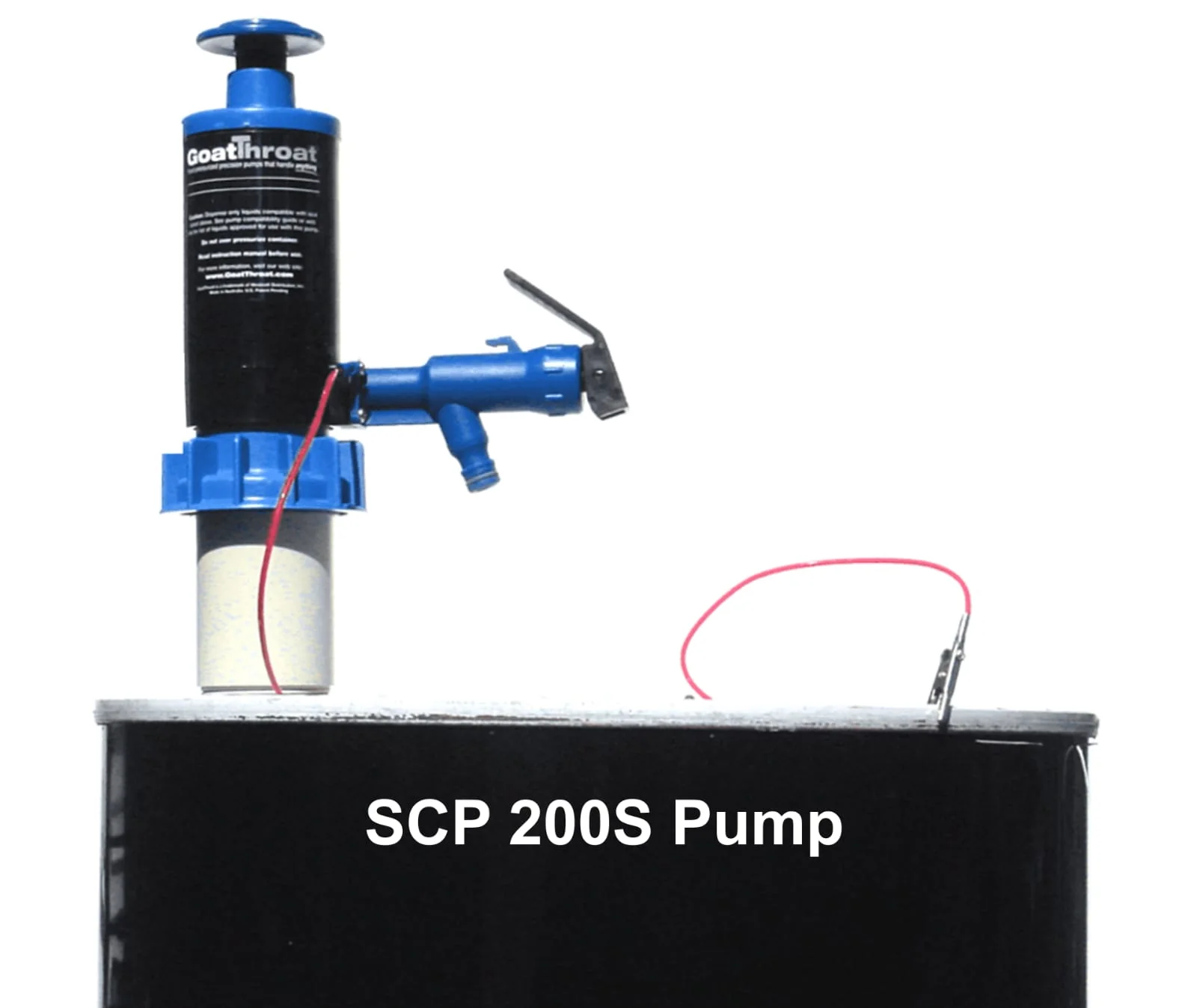

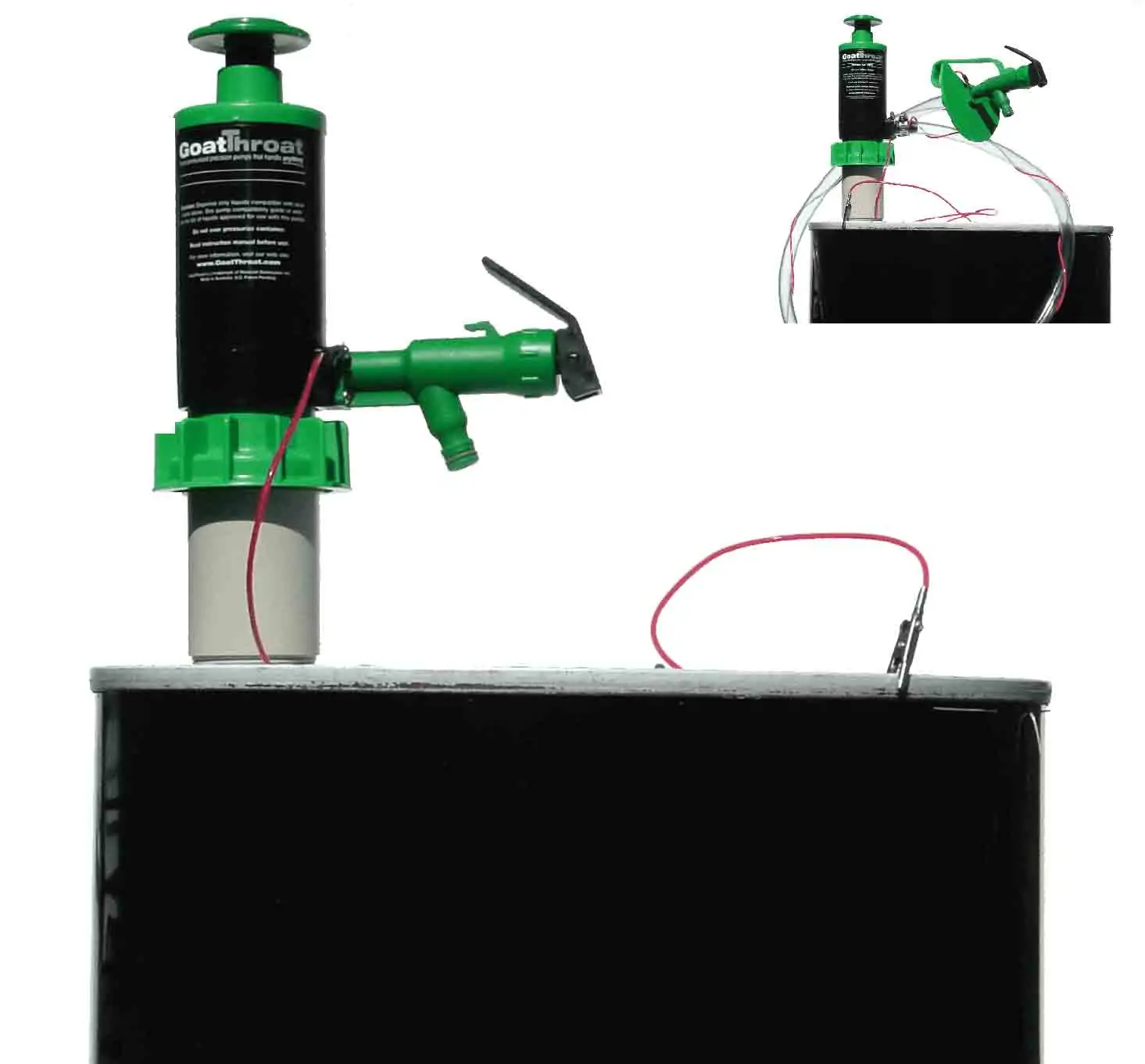

The Solution: “We decided to try a pressure action pump sourced from GoatThroat Pumps,” said Stiles. “These polypropylene pumps proved reliable, and permitted us to keep our drums safely in an upright position. We now have 2 rigs. At the fixed location, we utilize fixed grounding and bonding wires that are hooked directly to the drum. We have added the air compressor adapter which, with only 2 psi, delivers the acetone to small containers for our labor force to use at their benches for ‘small work’.

The solution has proved ideal for dispensing on demand (shown above, right), and the same setup can also be used for larger mobile units (shown left), which fill 20-40 gal day tanks.

“At a rate of 4 gallons a minute, it takes one man about 12 minutes to fill the 40 gal tank,” said Stiles. “No more carrying buckets of acetone across the factory, which consumed the better part of 30 minutes and could hurt the employee’s back. We have replaced o-rings a couple of times, but the original pumps are still in use after 4 years. The new procedure is faster and safer, and has helped us exceed our environmental compliance requirements.”