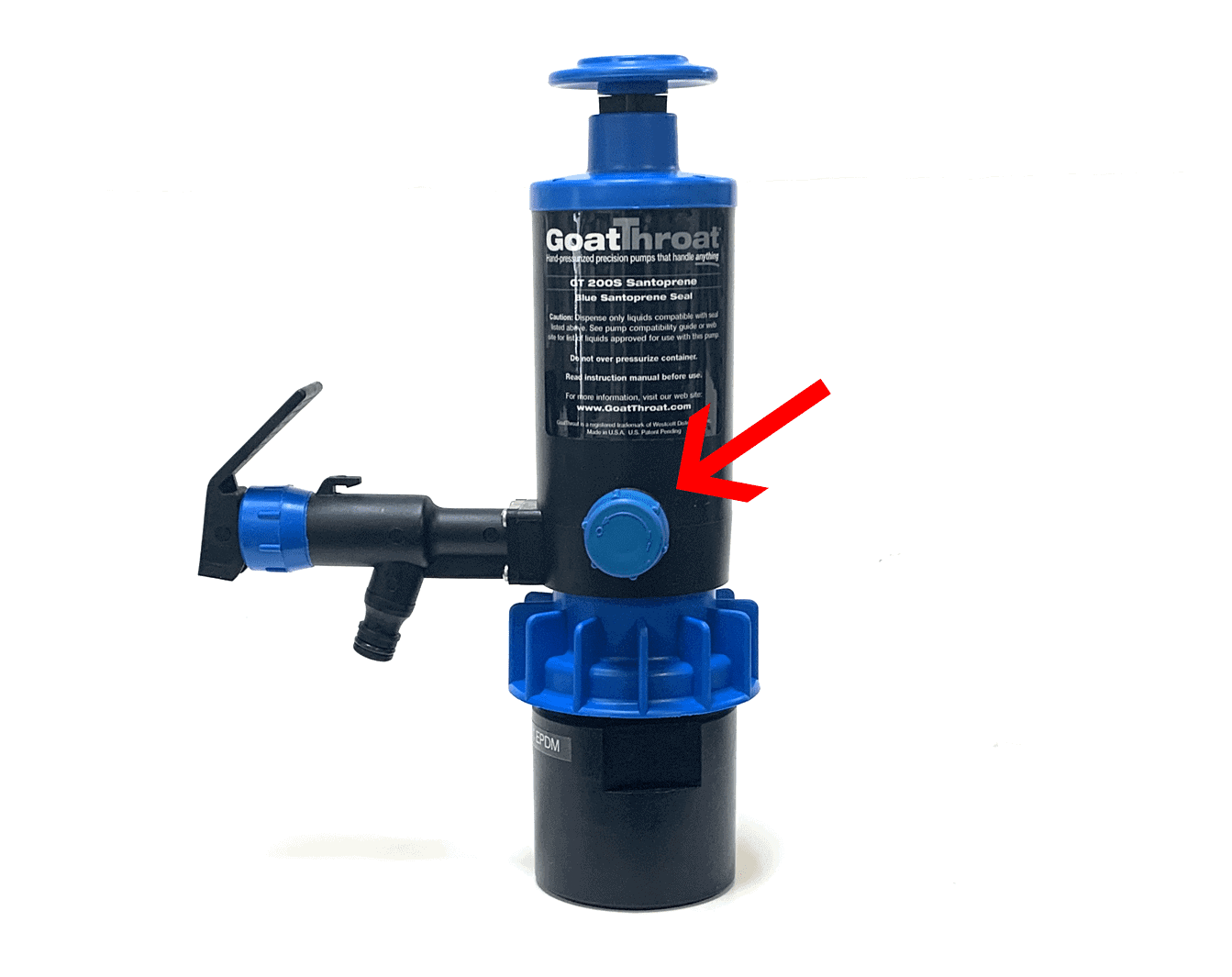

The Chemical Guide

is the key to success.

Once you tell us your chemical, our system searches the 2000+ chemicals in the Guide and tells you the correct materials of construction for your system from plastics, metals and gaskets all the way though hosing so that your system is fit for your exact use.